2025 Top Non Woven Fabric Making Machine Trends and Insights

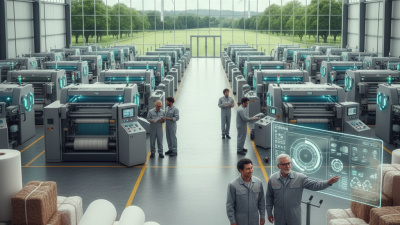

The landscape of the non woven fabric manufacturing industry is rapidly evolving, driven by technological advancements and shifting market demands. As we look towards 2025, understanding the emerging trends and insights related to non woven fabric making machines becomes increasingly crucial for manufacturers and stakeholders. These machines are at the forefront of producing versatile, innovative materials that cater to various applications across industries, including healthcare, agriculture, and automotive.

In recent years, the development of non woven fabric making machines has seen significant progress, characterized by enhanced efficiency, sustainability, and automation. Key trends, such as the integration of smart technologies and environmentally-friendly materials, are reshaping the production processes and capabilities of these machines. As manufacturers strive to meet stringent quality standards and consumer preferences, exploring the advancements in non woven fabric making machines will be essential for maintaining a competitive edge in the market.

This article delves into the notable trends and insights surrounding non woven fabric making machines, highlighting the transformative impact they have on production methods and the overall industry landscape. By examining the latest innovations and future directions, we aim to provide a comprehensive overview that can guide industry players in navigating the complexities of this dynamic sector.

2025 Trends in Non Woven Fabric Production Technologies

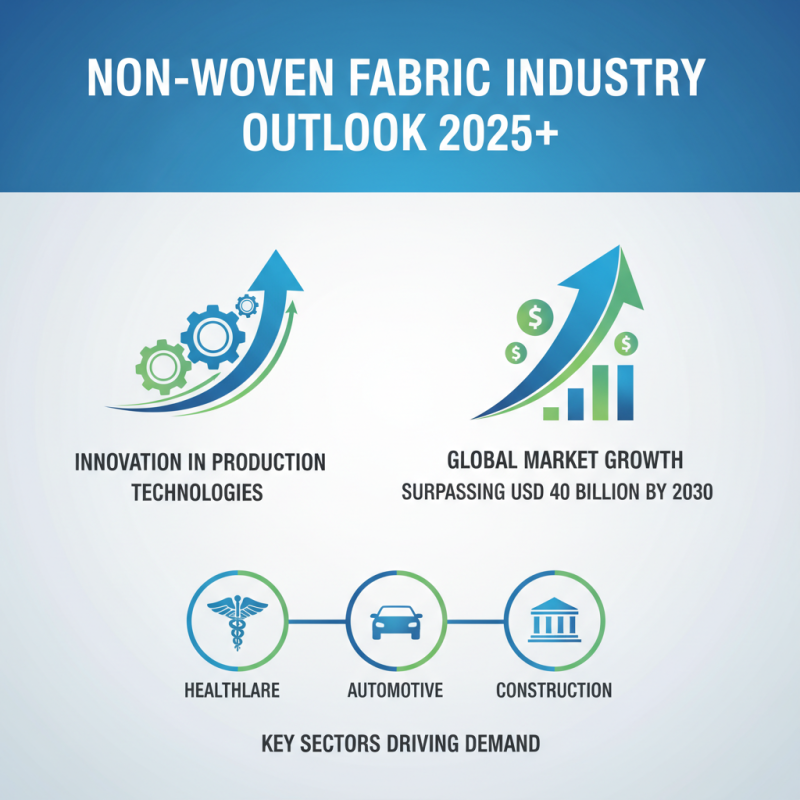

The non-woven fabric industry is on a significant trajectory toward innovation as we approach 2025, especially in production technologies. The global market for non-woven fabrics is expected to grow substantially, with projections indicating a market size that could surpass USD 40 billion by the end of the decade. This growth highlights the increasing importance of these materials across various sectors, including healthcare, automotive, and construction.

Recent trends reveal that the production techniques are evolving, with a notable shift towards technologies like spunbond and meltblown, which cater to the rising demand for high-performance fabrics. Materials such as polyester and polypropylene are predominant, driven by their versatility and durability. Additionally, the construction segment is expected to witness a significant share of the non-woven fabric market due to increasing infrastructural projects globally. As industry participants gather at events such as the recent non-woven fabric industry chain development conference, the focus is on harnessing these technologies to enhance product quality and operational efficiency within the rapidly growing sector.

Key Innovations in Non Woven Fabric Making Machines in 2025

In 2025, the landscape of non woven fabric making machines is set to evolve significantly, driven by key innovations that enhance efficiency, sustainability, and versatility. One prominent trend is the integration of automation and AI technologies, which streamline production processes and reduce labor costs. These smart machines not only optimize fiber use but also enable real-time monitoring of quality, ensuring consistent output with minimal waste.

Another significant innovation includes the development of eco-friendly machinery designed to utilize biodegradable materials. As consumer demand for sustainable products increases, manufacturers are investing in machines that can process alternative fibers, such as hemp and bamboo. This shift not only supports environmental goals but also opens new markets for non woven fabric products.

**Tip:** When considering an upgrade for your production facility, evaluate machines that offer modular features. This flexibility allows for adaptation to changing market demands without the need for complete overhauls, saving both time and resources. Additionally, invest in equipment that has proven energy-efficient capabilities to not only enhance productivity but also lower operational costs.

2025 Top Non Woven Fabric Making Machine Trends and Insights

| Trend | Description | Key Innovation | Impact |

|---|---|---|---|

| Sustainability | Growing demand for eco-friendly fabric solutions. | Biodegradable raw materials. | Reduces environmental impact. |

| Automation | Integration of AI and robotics in production lines. | Smart manufacturing processes. | Increases efficiency and reduces labor costs. |

| Customization | Need for personalized fabric solutions. | Flexible production systems. | Meets diverse consumer demands. |

| Digital Printing | Adoption of digital technologies for design. | High-resolution digital fabric printing. | Enables intricate designs and swift production. |

| Smart Fabrics | Development of fabrics with embedded technology. | Integration of sensors and electronics. | Offers enhanced functionality for end-users. |

Sustainability in Non Woven Fabric Manufacturing Processes

The non-woven fabric industry is increasingly focusing on sustainability as global awareness of environmental issues grows. Manufacturers are exploring innovative processes that reduce waste and energy consumption throughout the production cycle. Techniques such as using biodegradable materials, recycling post-consumer waste, and incorporating eco-friendly polymers are gaining traction. By utilizing these methods, companies aim to minimize their carbon footprint while maintaining the quality and performance of their fabrics.

In addition to raw material sourcing, manufacturers are also enhancing their operational efficiencies. Advanced technologies such as automation and IoT integration are being deployed to streamline manufacturing processes, reduce resource usage, and improve overall productivity. These advancements not only bolster sustainability efforts but also drive cost-effectiveness and boost competitiveness in the market. As consumers increasingly demand eco-conscious products, non-woven fabric manufacturers that prioritize sustainable practices stand to gain significant market advantages, aligning economic viability with environmental stewardship.

Market Demand and Growth Factors for Non Woven Fabrics in 2025

The demand for non-woven fabrics is expected to surge significantly by 2025, driven by various growth factors across multiple industries. One of the primary drivers is the increasing application of non-woven materials in hygiene products, such as diapers and feminine care items. The global preference for disposable products, fueled by health and hygiene concerns, is projected to elevate market growth. Additionally, the robust advancements in non-woven fabric technologies further underpin the demand as manufacturers seek innovative solutions for better performance and sustainability.

Furthermore, the global mattress fabric market exemplifies the potential for growth in this sector, with projections indicating a rise from $6.12 billion in 2025 to $8.58 billion by 2032. This growth reflects the broader trends within the textile market, which is anticipated to surpass $2.01 trillion by 2034. As consumer awareness regarding the comfort and quality of bedding products expands, there is a corresponding increase in demand for non-woven fabrics that offer improved durability and comfort. This growth narrative highlights a clear trajectory of rising market demand, positioning non-woven fabric making as a pivotal industry trend in the coming years.

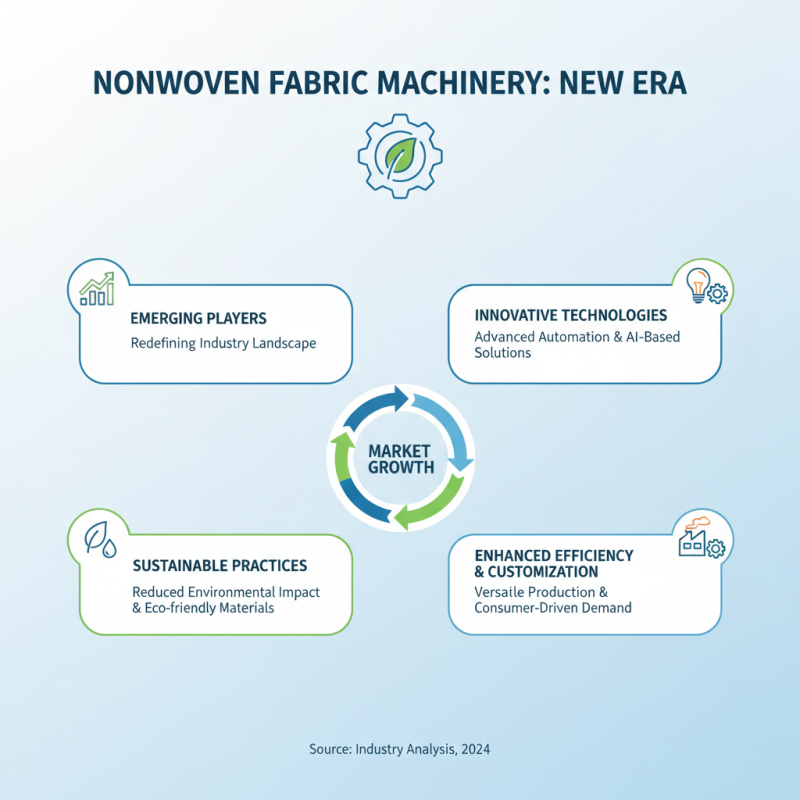

Emerging Players in the Non Woven Fabric Machinery Market

The non woven fabric machinery market is witnessing a surge in emerging players who are redefining the industry landscape with innovative technologies and sustainable practices. These new entrants are focusing on enhancing production efficiency while also reducing environmental impact, a demand increasingly driven by consumer preferences for eco-friendly materials. Companies specializing in advanced automation and AI-based solutions are beginning to dominate, providing cutting-edge machinery that allows for versatility in production and customization.

Additionally, collaboration and partnerships among these emerging players are becoming a key strategy for gaining a competitive edge. By joining forces, these companies can leverage shared expertise and resources to develop state-of-the-art machinery that meets the evolving needs of diverse sectors, including healthcare, hygiene, and textiles. As the market continues to expand, these dynamic newcomers are poised to disrupt traditional manufacturing processes, emphasizing a shift towards smarter, more sustainable production methods that align with global sustainability goals.

Related Posts

-

Top Non Woven Fabric Suppliers You Need to Know for Your Business

-

Top 10 Innovative Machines Transforming the Textile Industry in 2023

-

What is Nonwoven Industry: Insights into Its Growth and Applications

-

2025 Top 10 Airlaid Nonwoven Products Transforming the Hygiene Industry Landscape

-

Why Non Woven Fabric Manufacturers Are Key to Sustainable Industry Solutions

-

2025 How to Choose the Best Non Woven Cutting Machine for Your Needs