Best Non Woven Fabric Making Machines for Efficient Production?

The demand for non woven fabrics has surged in recent years. A report by Smithers Pira estimates that the global market for non woven fabrics will reach $37 billion by 2024. This growth reflects the rising applications in sectors like hygiene, healthcare, and geotextiles. Consequently, investing in a high-quality non woven fabric making machine is essential for efficient production.

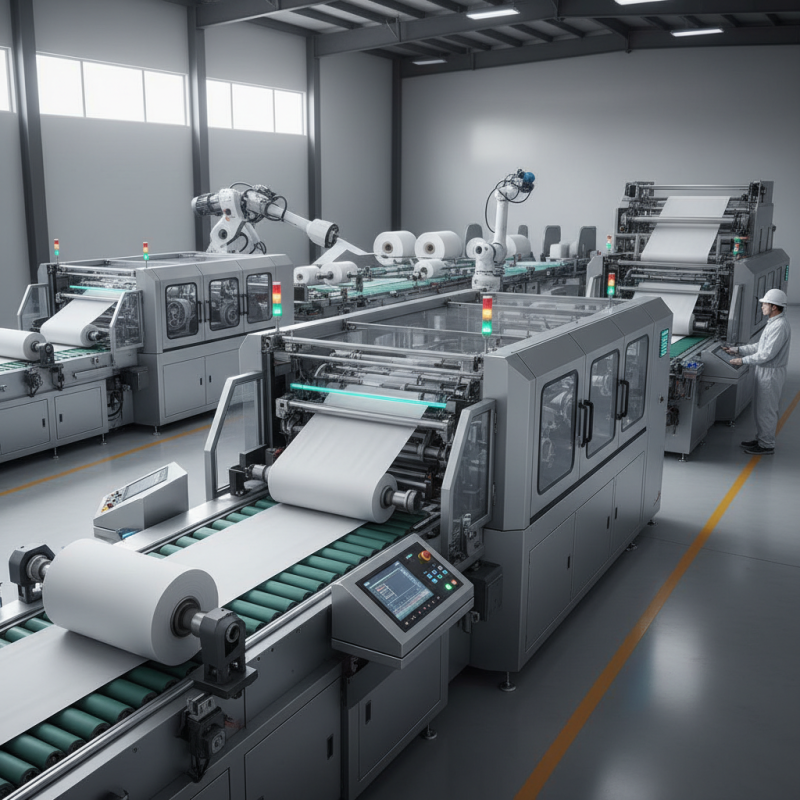

Manufacturers need to adopt advanced technology to stay competitive. Modern non woven fabric making machines offer features like high speed and energy efficiency. These features not only enhance productivity but also reduce operational costs. However, choosing the right machine can be a challenge. There are various brands and specifications available. Each presents unique benefits but also potential drawbacks.

The industry faces some challenges too. Not all machines deliver the promised performance. Some may require frequent adjustments. This can disrupt production and increase costs. It's critical for businesses to conduct thorough market research before making a purchase. Reflecting on previous investments can help identify better options. Investing wisely in the right non woven fabric making machine can lead to long-term benefits.

Types of Non Woven Fabric Making Machines Available in the Market

When exploring the types of non-woven fabric making machines, several options are available in the market. These machines can efficiently produce various non-woven textiles. Some common types include spunbond machines, meltblown machines, and needlepunch machines. Each type serves specific applications and materials.

Spunbond machines are frequently used for lightweight fabrics. They create a fabric by bonding fibers that are spun and laid down in a web. This process is suitable for products like disposable medical gowns and geotextiles.

Meltblown machines, on the other hand, produce fine fibers. These are essential for applications requiring high filtration properties, such as masks and air filters.

Then there are needlepunch machines that provide durability and texture. They involve punching barbed needles through layers of fiber, creating a robust fabric. However, this process can be time-consuming and might lead to inconsistencies in the final product.

Evaluating machine capabilities according to production needs is crucial. Make sure to weigh efficiency against specific use cases to optimize output.

Key Features to Consider When Choosing Non Woven Fabric Machines

When selecting non woven fabric making machines, certain key features are crucial. These machines must efficiently produce high-quality fabrics with minimal waste. Reports indicate that the non woven fabric market reached approximately $40 billion in 2022. This growth emphasizes the need for reliable machinery in production lines.

One must consider the technology used in the machines. For instance, the type of bonding process—thermal, chemical, or mechanical—can affect the fabric's properties. A 2023 data analysis revealed that thermal bonding accounted for 45% of non woven fabric production. Manufacturers should also pay attention to the machine's capacity and speed. A high-capacity machine can significantly improve production efficiency, yet may require a larger initial investment.

Furthermore, energy consumption is a growing concern. With rising energy costs, machines that consume less power are becoming essential. Some sources suggest that machines with energy-efficient motors can reduce electricity usage by up to 30%. However, balancing cost and efficiency can be challenging. Maintenance considerations are also important; machines requiring frequent adjustments can hinder production flow.

Best Non Woven Fabric Making Machines for Efficient Production

| Machine Type | Production Capacity (kg/h) | Power Consumption (kW) | Fabric Thickness (mm) | Automation Level |

|---|---|---|---|---|

| Spunbond Machine | 300 | 70 | 0.5 - 3 | Fully Automatic |

| SMS Machine | 250 | 60 | 0.3 - 2.5 | Semi-Automatic |

| Meltblown Machine | 200 | 50 | 0.1 - 1.5 | Fully Automatic |

| Needle Punching Machine | 150 | 40 | 0.5 - 5 | Manual |

| Thermal Bonding Machine | 180 | 65 | 0.8 - 4 | Semi-Automatic |

Advantages of Using Non Woven Fabric Production Equipment

Non woven fabrics have gained immense popularity across multiple industries. The right production equipment plays a crucial role in achieving high efficiency. According to recent industry reports, the global non woven fabric market is expected to reach USD 42 billion by 2026, growing at a CAGR of 8.4%. This growth is driven by demand in sectors like hygiene, medical, and agriculture.

Using proper non woven fabric production equipment offers several advantages. It ensures uniformity in fabric quality and reduces production time. These machines are often designed for flexibility, allowing various fabric types to be produced efficiently. A key benefit is their ability to minimize waste. For instance, high-quality machines can achieve material utilization rates over 90%. This not only reduces costs but also promotes sustainability.

Tips: Focus on machine adaptability to meet changing market demands. Ensure your team receives sufficient training to maximize equipment potential. Continuous evaluation of production processes can highlight areas for improvement. Keeping up with technological advancements can enhance efficiency but requires an open mindset. A willingness to adapt is essential, as outdated practices may hinder growth.

Innovative Technologies in Non Woven Fabric Manufacturing Machines

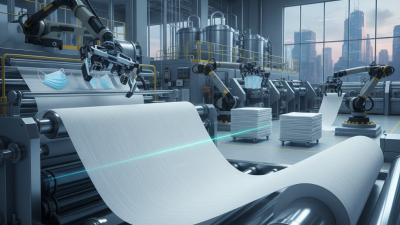

Innovative technologies in non-woven fabric manufacturing are transforming the industry. Modern machines utilize advanced techniques for improved efficiency. These machines integrate automation to reduce labor costs. For example, some models can operate with minimal human intervention. This not only saves time but also enhances production capacity.

Recent advancements include the use of ultrasonic technology. This method creates stronger bonds between fibers, leading to durable products. Additionally, some machines now feature energy-efficient designs. This can significantly lower operational costs and environmental impact. However, as these technologies evolve, they are often costly to implement initially.

Moreover, the role of data analytics in production should not be overlooked. By monitoring the manufacturing process, companies can identify inefficiencies. This data-driven approach allows for continuous improvement. It’s not just about producing more; it’s about producing better. Yet, companies face challenges in training personnel to use these complex systems effectively. The balance between innovation and usability remains a thought-provoking issue.

Maintenance Tips for Efficient Operation of Non Woven Fabric Machines

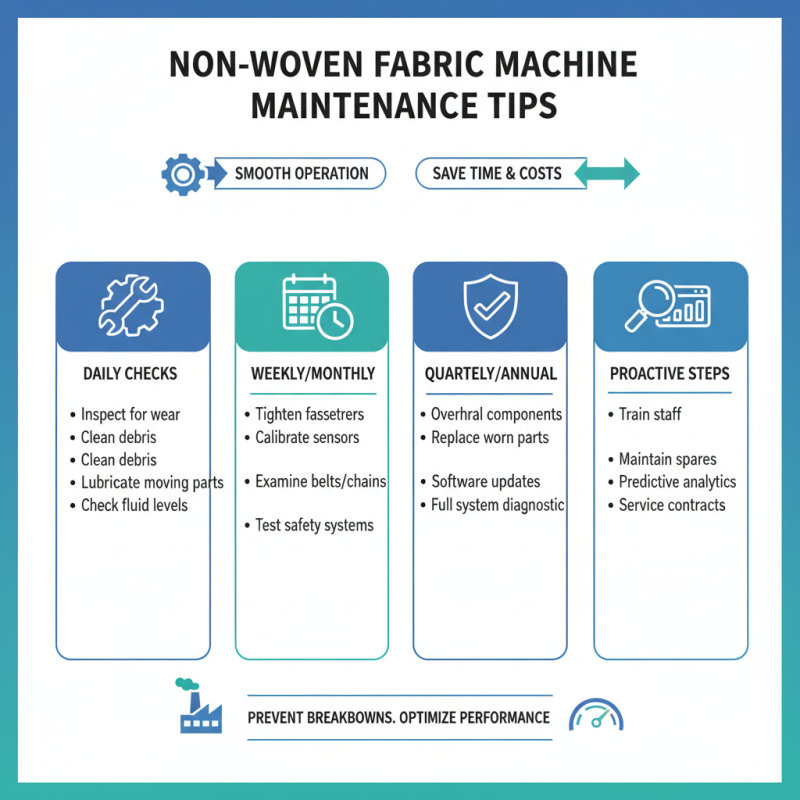

Maintaining non-woven fabric machines is crucial for smooth operations. Regular maintenance prevents unexpected breakdowns. It can save time and costs in the long run. Here are some maintenance tips to ensure efficient functionality.

Check the machine's components often. Look for wear and tear, especially on moving parts. Any loose screws or belts can lead to malfunction. Cleaning the machine regularly is important, too. Dust and debris can affect performance. Remove any accumulated residues from the surfaces.

Don't overlook lubrication. A well-lubricated machine runs more smoothly. However, avoid over-lubricating, as it can lead to mess and inefficiency. Remember to keep an eye on the electrical connections. Frayed wires can pose safety hazards. Take action to fix any detected issues promptly.

Related Posts

-

How to Choose the Best Non Woven Fabric Manufacturing Machine for Your Needs

-

How to Choose the Best Non Woven Cloth Cutting Machine for Your Needs?

-

What is the Nonwoven Industry and its Impact on Modern Manufacturing

-

How to Choose the Best Non Woven Fabric for Your Projects

-

2026 Best Innovations in the Nonwoven Industry for Sustainable Solutions?

-

2026 How to Choose the Right Non Woven Fabric for Your Project?