Best Non Woven Fabric Machines for Efficient Production and Quality Assurance

The production of non woven fabrics has gained significant traction in recent years due to their versatility and wide range of applications across various industries, from medical to automotive. A key component in achieving high-quality non woven fabric is the non woven fabric machine, which plays a pivotal role in ensuring efficient production processes that meet stringent quality standards. As manufacturers increasingly seek to enhance productivity while maintaining top-notch quality, selecting the right machinery becomes essential.

This introduction aims to explore the best non woven fabric machines available today, highlighting their features that contribute to efficiency and quality assurance. By examining technological advancements and innovative designs, we will uncover how these machines streamline production workflows and meet the evolving demands of the market. Ultimately, this guide serves as a comprehensive resource for manufacturers looking to invest in non woven fabric machinery that enhances their operational capabilities and supports the growing need for sustainable materials.

Best Non Woven Fabric Machines: Performance Metrics and QA Standards

When selecting non-woven fabric machines, understanding performance metrics and quality assurance standards is paramount for ensuring efficient production. Performance metrics entail aspects such as throughput rate, energy consumption, and fabric strength. These factors directly influence the machine's efficiency and the quality of the final product. A machine that maintains high throughput while consuming less energy can significantly reduce operational costs, making it essential to analyze these metrics thoroughly.

Quality assurance standards play a crucial role in maintaining the consistency of the products. Machines should comply with industry standards that govern various aspects of fabric quality, such as durability, texture, and appearance. Implementing strict QA protocols during the production process can help identify defects early, thus minimizing waste and maximizing productivity. Regular maintenance and calibration of machines also contribute to adhering to these standards.

Tips: To enhance the performance of non-woven fabric machines, consider investing in training programs for operators to ensure they are well-versed in the latest technologies and quality assurance practices. Regular audits of the production process can help identify areas for improvement, leading to higher efficiency. Lastly, utilizing advanced monitoring systems can provide real-time data, allowing for quicker adjustments to maintain optimal performance and quality.

An Overview of Non Woven Fabric Production Processes and Technologies

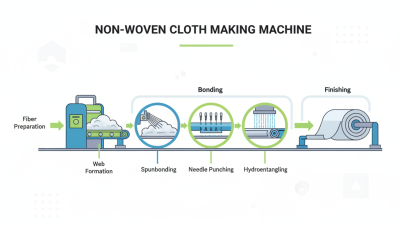

The production of non-woven fabrics involves several distinct processes and technologies that contribute to their efficiency and quality. Among the primary methods are spunbond, meltblown, and needlepunch techniques. Spunbond involves extruding thermoplastic polymers into continuous filaments that are laid down and bonded together. This method yields high strength and durability, making it suitable for a wide array of applications, from medical supplies to automotive components. Meltblown technology, on the other hand, utilizes high-velocity air to draw and break filaments into ultra-fine fibers, primarily used for filtration products and insulation.

In addition to these methods, advancements in technology play a crucial role in enhancing the production efficiency and ensuring quality assurance. Continuous monitoring systems, for example, use sensors and data analytics to track production parameters in real-time, allowing manufacturers to promptly address any deviations from desired quality standards. Furthermore, automation and robotics facilitate seamless operation and minimize human error, driving consistent output. The integration of these diverse processes and cutting-edge technologies not only optimizes production capabilities but also enhances the overall performance and longevity of the non-woven fabrics produced.

Non Woven Fabric Production Efficiency and Quality Metrics

Key Features of High-Efficiency Non Woven Fabric Machines

When looking for high-efficiency non-woven fabric machines, certain key features are essential for ensuring optimal production and quality assurance. One of the most critical aspects is the machine's production capacity, which can vary significantly. According to industry reports, modern non-woven fabric machines can produce anywhere from 50 to 300 kilograms of fabric per hour, depending on the configuration and technology used. This allows manufacturers to scale their operations according to market demands.

Another important feature to consider is automation. Advanced non-woven fabric machines incorporate automation technologies that minimize human error and enhance consistency in product quality. Automated systems can regulate parameters such as temperature, speed, and tension, ensuring that the final product meets the required specifications. Reports suggest that automation can reduce production times by up to 30%, making it a worthwhile investment for companies aiming to improve efficiency.

**Tip:** When selecting a non-woven fabric machine, ensure it includes features such as energy efficiency and eco-friendly operation modes. This not only helps reduce operational costs but also aligns with global sustainability trends, as the non-woven industry increasingly focuses on reducing its environmental footprint.

Additionally, built-in quality control mechanisms can significantly enhance product consistency. Machines equipped with sensors and monitoring systems allow for real-time quality assurance, detecting defects as they occur and adjusting the production process accordingly. Data shows that implementing such technology can lead to a 20% reduction in waste during the manufacturing process, ensuring that both resources and costs are optimized.

Impact of Machine Automation on Quality Assurance in Non Woven Production

The automation of machinery in non-woven fabric production has significantly enhanced quality assurance processes within the industry. According to a report by Smithers Pira, the global non-woven fabric market is expected to grow by 5.5% annually, reaching a value of approximately $40 billion by 2027. This growth has prompted manufacturers to invest in advanced automated machinery that not only optimizes production efficiency but also ensures consistent product quality. Automated systems are equipped with sophisticated sensors and technologies that monitor fabric properties in real-time, drastically reducing human error and enhancing quality control measures.

Tips for optimum efficiency include regular maintenance of automated machines and training operators to understand automated systems thoroughly. Proper upkeep can reduce downtime and enhance the lifespan of equipment, while well-trained staff can address any issues that arise swiftly, ensuring uninterrupted production flow. Additionally, integrating data analytics into production can provide insights into quality trends and areas for improvement, allowing manufacturers to make informed decisions about their processes.

As machine automation continues to evolve, the integration of Artificial Intelligence (AI) is becoming more prevalent in quality assurance. According to a study from the Journal of Industrial Technology, businesses that adopt AI-driven machines for monitoring fabric quality report a reduction in defects by up to 30%. Implementing such technologies not only boosts overall productivity but also aligns with the industry's shift towards sustainable manufacturing practices, where quality assurance and efficiency go hand in hand.

Comparative Analysis of Leading Non Woven Fabric Machinery Brands and Models

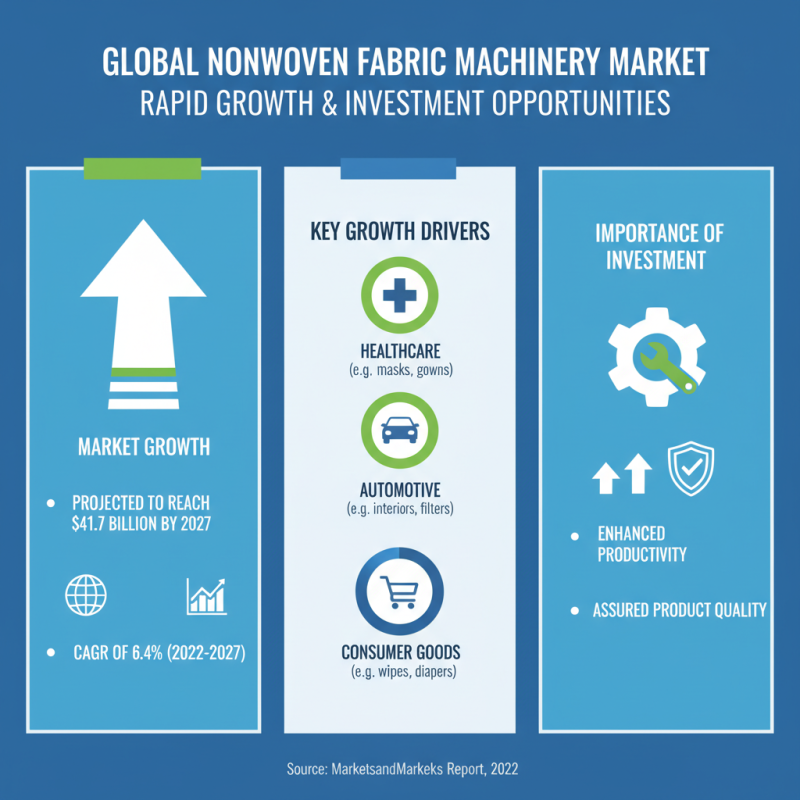

The market for non woven fabric machinery is growing rapidly, driven by increased demand across various sectors, including healthcare, automotive, and consumer goods. According to a report by MarketsandMarkets, the global non woven fabric market is projected to reach USD 41.7 billion by 2027, growing at a CAGR of 6.4% from 2022. This growth underlines the importance of investing in efficient and high-quality non woven fabric machines, which are critical for manufacturers aiming to enhance productivity and ensure product quality.

A comparative analysis of leading non woven fabric machinery highlights several key attributes that separate top-tier models from their competitors. For instance, machines equipped with advanced automation technologies significantly reduce production time while maintaining consistent quality. Furthermore, features like multi-layer forming capabilities and adjustable fiber orientation allow manufacturers to produce a broader range of products. Reports indicate that machines with integrated quality control systems can decrease defect rates by up to 30%, ensuring that manufacturers meet stringent quality assurance standards.

Additionally, energy efficiency is becoming an essential factor in machinery selection. Data from industry surveys suggest that machines designed with enhanced energy-saving features can cut operational costs by nearly 15%, contributing to a more sustainable production process. As manufacturers increasingly prioritize environmental responsibility, the demand for machines that not only optimize production efficiency but also embrace sustainability initiatives will continue to rise. This trend indicates a shift towards technologies that support both economic and ecological goals in the non woven fabric industry.

Related Posts

-

How to Choose the Best Non Woven Fabric Manufacturing Machine for Your Needs

-

What is a Non-Woven Cloth Making Machine and How Does It Work?

-

2025 Top Non Woven Fabric Making Machine Trends and Insights

-

Why Non Woven Fabric is Revolutionizing Industries and Everyday Products

-

Top Non Woven Fabric Suppliers You Need to Know for Your Business

-

2025 How to Choose the Best Non Woven Cutting Machine for Your Needs