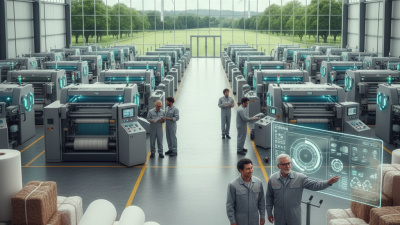

How to Choose the Best Non Woven Fabric Manufacturing Machine for Your Needs

When it comes to selecting the right non woven fabric manufacturing machine, making an informed choice can be the difference between success and stagnation in your business. According to Dr. Emily Thompson, a leading expert in the non woven fabric industry, "Choosing the right machinery is crucial for optimizing production efficiency and enhancing product quality." With the rapid advancements in technology and the diverse applications of non woven fabrics, understanding the specific requirements of your operation is more important than ever.

In an industry characterized by varying materials and production processes, it's essential to evaluate the capabilities and features of potential machines. Factors such as production speed, energy efficiency, and the types of non woven fabrics you intend to produce should guide your decision-making process. As Dr. Thompson advises, assessing these elements not only helps in meeting current demand but also positions your business strategically for future growth.

Investing in a non woven fabric manufacturing machine is a significant commitment, and careful consideration will ensure that you select equipment that aligns with your business goals. By leveraging expert insights and understanding the intricacies of your manufacturing needs, you can make a choice that not only meets today's standards but also paves the way for innovation and competitiveness in the marketplace.

Understanding Non Woven Fabric: Types and Applications

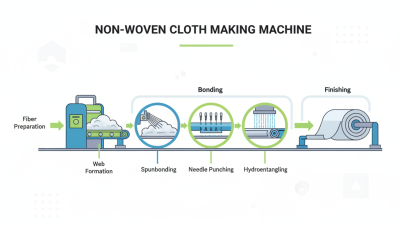

Non woven fabrics are versatile materials made from synthetic or natural fibers that are bonded together through various methods, such as heat, chemical, or mechanical processes. These fabrics do not undergo traditional weaving or knitting, which results in unique properties and a wide range of applications. Understanding the different types of non woven fabrics, such as spunbond, meltblown, and bonded fabrics, is essential to choose the most suitable manufacturing machine for specific needs.

Spunbond fabrics are known for their strength and durability, making them ideal for packaging, agricultural covers, and hygiene products like diapers and feminine hygiene items. On the other hand, meltblown fabrics possess finer fibers, creating a soft texture, often used in filtration applications, medical face masks, and insulation materials. Bonded fabrics, formed by adhesive bonding, are generally used in applications that require higher absorbency, such as wipes and medical gowns. By understanding these types and their respective applications, manufacturers can make informed decisions when selecting the appropriate non woven fabric manufacturing machine that aligns with their production goals.

Key Features to Look for in Manufacturing Machines

When selecting a non-woven fabric manufacturing machine, it's essential to consider several key features that align with your production requirements. First and foremost, the machine's versatility in handling various raw materials is crucial. Look for machines that can process different types of fibers, as this flexibility allows for the creation of a wider range of products. Additionally, compatibility with both natural and synthetic materials can significantly enhance your production capabilities.

Another vital feature is the machine’s efficiency and speed. A high production rate, while ensuring consistent quality, can dramatically affect your operational efficiency. Pay attention to the machine's automation level; advanced machines often come equipped with automated controls that reduce manual intervention, improving productivity and minimizing human error. Furthermore, consider the ease of maintenance and accessibility of components, as machines that allow for simple upkeep will help minimize downtime and ensure longevity.

Finally, energy consumption is an important aspect to evaluate. Machines designed with energy-efficient technologies can help reduce operating costs over time. Evaluate the machine's energy ratings and operational efficiency to find an option that supports sustainable practices while still meeting your production demands. Making informed decisions based on these key features will enable you to choose the best non-woven fabric manufacturing machine tailored to your specific needs.

Evaluating Production Capacity and Efficiency Requirements

When selecting a non woven fabric manufacturing machine, one of the most critical factors to consider is its production capacity. Understanding your anticipated output needs is essential for matching a machine with your operational goals. Start by evaluating the volume of non woven fabric you plan to produce on a daily or weekly basis. High-capacity machines are ideal for large-scale production environments, where consistent output and efficiency are paramount. Conversely, if your production demands are modest, you may benefit from a smaller, more flexible machine that can accommodate varying orders without the need for substantial investment.

In addition to capacity, efficiency plays a vital role in the overall stringency of your operations. Look for machines that offer features that enhance productivity, such as automated processes, quick changeovers, and energy-efficient designs. These aspects can significantly reduce downtime and operational costs, allowing for more cost-effective production. Consider conducting a thorough analysis of the machine's specifications and exploring user reviews to gauge how well it meets efficiency benchmarks in real-world conditions. Prioritizing these factors ensures that the machine you choose aligns with your production needs while maximizing both output and efficiency.

Assessing Cost and Budget Considerations for Your Machinery

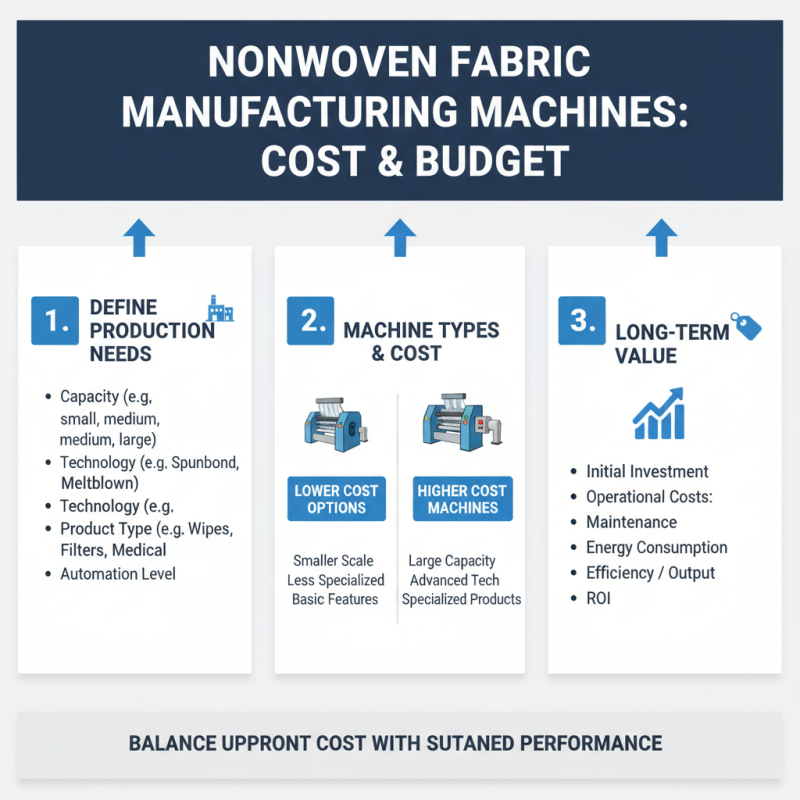

When assessing cost and budget considerations for non woven fabric manufacturing machines, it's crucial to start by defining your specific production needs. The capacity, technology, and features of the machine directly influence its price. Lower-cost options may suffice for smaller operations or those producing less specialized products, whereas larger manufacturers often require machines with advanced capabilities, which tend to come at a higher price point. Evaluating the trade-offs between initial investment and long-term operational costs, such as maintenance, energy consumption, and efficiency, is essential for making an informed decision.

Additionally, consider the financing options and potential return on investment (ROI) associated with the machinery. Understanding how the machine will impact your production output and quality can help justify its cost. It may be wise to allocate budget for training personnel and integrating the new machine into your existing workflow. By taking a comprehensive approach to budgeting, including all related expenses beyond the purchase price, you can ensure that you select a non woven fabric manufacturing machine that meets your operational requirements without compromising financial stability.

Selecting the Right Supplier and After-Sales Support Options

When selecting a non-woven fabric manufacturing machine, the choice of supplier and after-sales support options is crucial. Many manufacturers overlook this aspect, focusing solely on machine specifications and pricing. However, a study by the Nonwovens Industry Association highlights that 30% of companies reported reduced downtime and improved production efficiency when partnering with a responsive supplier who offers robust after-sales support. Such partnerships can ensure timely maintenance and quick resolution of any operational issues, directly affecting profitability.

One key tip is to assess the supplier's after-sales service options. Look for suppliers who provide comprehensive training, regular maintenance checks, and a responsive customer service team. According to industry analysts, suppliers with strong service commitments can extend the life of your machinery by up to 20%. Another important factor is to inquire about the availability of spare parts and the supplier’s ability to provide them promptly, as delays can disrupt production significantly.

Additionally, consider their reputation in the industry. Engaging with other manufacturers who have used the same supplier can provide insights into their reliability and support efficiency. A company’s solid review and referral network can be indicative of their commitment to customer satisfaction and support post-purchase. This not only ensures proper operation but also enhances overall investment returns in the long run.

Related Posts

-

2025 Top Non Woven Fabric Making Machine Trends and Insights

-

What is a Non-Woven Cloth Making Machine and How Does It Work?

-

Top Non Woven Material Applications in 2025 and Future Trends

-

Top 10 Innovative Machines Transforming the Textile Industry in 2023

-

Top Non Woven Fabric Suppliers You Need to Know for Your Business

-

Why Non Woven Fabric Manufacturers Are Key to Sustainable Industry Solutions