How to Choose the Best Non Woven Cloth Cutting Machine for Your Needs?

Choosing the right non woven cloth cutting machine can be overwhelming. With various options available, decision-making becomes challenging. Industry expert John Smith states, "Selecting the right machine is crucial for efficiency." He emphasizes the impact of choosing wisely.

A non woven cloth cutting machine should meet specific needs. Consider factors like material types and cutting precision. Machines vary in capabilities, making it essential to align features with your requirements. Understanding these details can improve your production process.

Yet, not every machine suits every operation. Some might perform poorly under heavy workloads. Reflecting on past experiences aids in making informed choices. Assessing reviews and expert opinions can be beneficial in this decision-making phase.

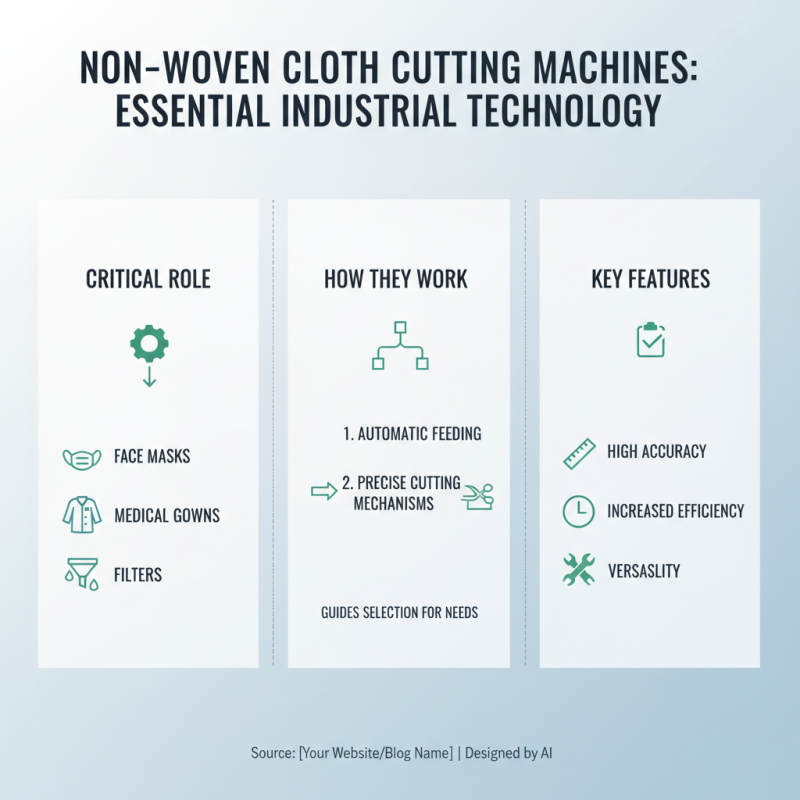

Understanding Non Woven Cloth Cutting Machines and Their Applications

Non woven cloth cutting machines play a critical role in various industries. They are essential for creating products like face masks, medical gowns, and filters. Knowing how these machines work can guide you in selecting the right one for your needs. Their design typically includes features like automatic feeding and precise cutting mechanisms.

Consider what materials you will use. Different machines have varying capabilities for thickness and type. Some may excel with lightweight materials, while others can handle heavier fabrics. This affects the quality of the final product. Make sure to research machine specifications carefully.

Here are some tips for choosing the best machine: Test the machine before purchasing. A demo can reveal its efficiency. Think about future needs, too. Will you expand your production? Make note of possible upgrades. Don’t forget to evaluate the available support and maintenance services. Each machine may offer different levels of assistance, which can be crucial for long-term success.

Key Features to Consider When Choosing a Cutting Machine

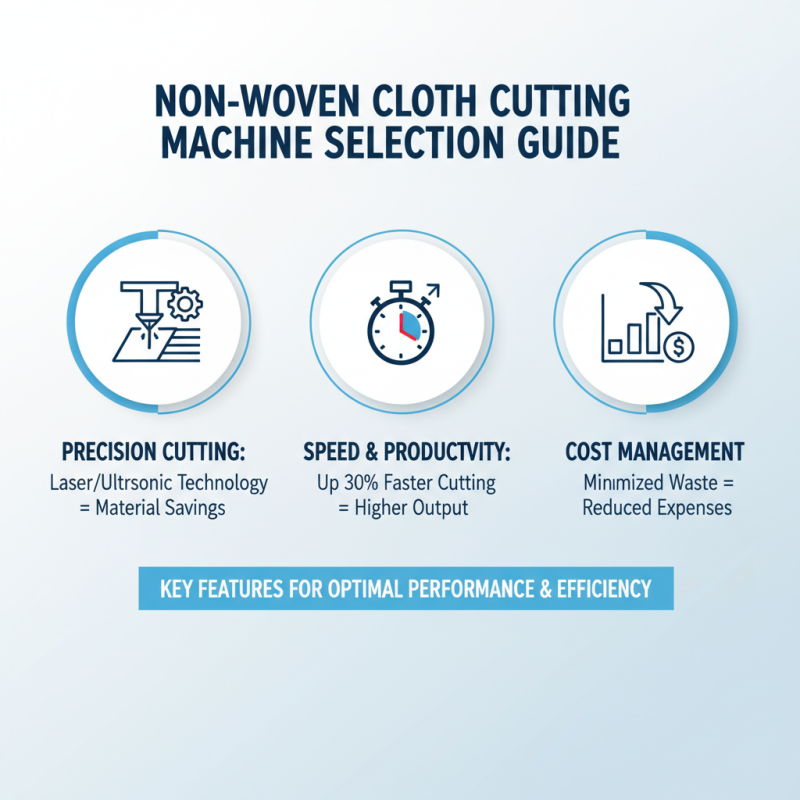

When choosing a non-woven cloth cutting machine, several key features must be considered. Precision in cutting is paramount. Machines equipped with advanced laser or ultrasonic cutting technologies provide accuracy. According to industry reports, devices with these technologies improve cutting speeds by up to 30%. High precision minimizes material waste and enhances productivity, which is crucial for cost management.

Another important feature is the ease of operation. User-friendly interfaces contribute to a smoother workflow. Operators should be able to quickly learn how to use the machine. Machines with touchscreen controls are increasingly popular. They enhance user experience and reduce training time. A trade report highlighted that 85% of operators prefer machines with intuitive controls.

Durability and maintenance are additional considerations. Machines made from high-quality materials last longer. Regular maintenance ensures consistent performance, yet many companies overlook this. Establishing a maintenance schedule can prevent costly downtimes. Take note of warranties offered; a solid warranty reflects machine reliability.

**Tip:** Always read reviews from other users. Real experiences can provide insights into potential issues.

**Tip:** Consider the machine's compatibility with various non-woven materials. Flexibility in material handling can expand your production capabilities.

Types of Non Woven Cloth Cutting Machines Available in the Market

When selecting a non woven cloth cutting machine, understanding the types available is essential. The market offers various options. Common types include manual, semi-automatic, and fully automatic machines. Each type serves different user needs. For small businesses, manual models are often cost-effective. They require more operator involvement but are easier to maintain.

On the other hand, semi-automatic machines offer a balance. They reduce manual effort while maintaining some control over the cutting process. Reports indicate a growing preference for these due to efficiency. Fully automatic machines are a leap forward, providing speed and precision. For high-volume production, they are ideal. However, they come with higher costs.

While many machines boast advanced features, not all deliver reliably. Some may have issues with consistency. Research shows that 30% of users report dissatisfaction due to underperformance. It's vital to assess your needs carefully and seek machines with proven reliability. Each option comes with its pros and cons, which should be weighed based on production goals.

Evaluating Machine Performance and Efficiency for Your Projects

When selecting a non-woven cloth cutting machine, evaluating machine performance and efficiency is crucial. Data from recent industry reports indicates that cutting speed and precision significantly influence productivity. Many machines offer cutting speeds ranging from 30 to 120 meters per minute. However, the ideal speed depends on the material and project requirements.

Another important factor is energy consumption. Some machines utilize energy-efficient motors, which can reduce operational costs by up to 20%. Yet, not all models provide energy-saving features. Users may overlook this aspect, leading to higher long-term expenses. Additionally, consider the ease of use. Complex interfaces can lead to mistakes and inefficiencies, hindering workflow.

Speed and efficiency metrics should match your production goals. In the non-woven textile industry, a report showed that 70% of successful projects prioritize high efficiency and reduced downtime. Poor machine performance can result in waste and increased costs. Therefore, evaluating all aspects of a machine’s performance is essential before making a decision.

How to Choose the Best Non Woven Cloth Cutting Machine for Your Needs?

| Feature | Value |

|---|---|

| Cutting Speed | 20 m/min |

| Max Cutting Width | 1.6 m |

| Power Consumption | 3 kW |

| Cutting Accuracy | ±0.5 mm |

| Material Compatibility | PP, PET, SMS |

| Control System | PLC with Touch Screen |

| Weight | 800 kg |

| Warranty | 2 years |

Budget Considerations and Cost-Effectiveness in Your Purchase Decisions

When choosing a non-woven cloth cutting machine, budget plays a crucial role. Understanding your financial limits helps narrow options. Machines vary widely in price and features. Some affordable models may lack efficiency or durability. It’s important to assess what you truly need.

Look beyond the initial cost. Consider maintenance expenses, replacement parts, and energy usage. A cheaper machine may save money upfront, but long-term costs may add up. Some users find themselves spending more on repairs or lower productivity. Reflect on how this impacts your overall budget.

Think about the potential for growth. Investing in a slightly more expensive, higher-quality machine could pay off. If your production needs increase, having the right machine is vital. Do you often feel overwhelmed by equipment choices? Take time to evaluate your priorities.

Comparison of Non Woven Cloth Cutting Machines: Budget and Cost-Effectiveness

Related Posts

-

2025 How to Choose the Best Non Woven Cutting Machine for Your Needs

-

Top 2025 Non Woven Material Trends You Need to Know

-

What is Non Woven Fabric and How is it Used in Everyday Products

-

Top Non Woven Material Applications in 2025 and Future Trends

-

Why Non Woven Fabric Manufacturers Are Key to Sustainable Industry Solutions

-

2025 Top Non Woven Fabric Making Machine Trends and Insights