2026 How to Choose the Best Non Woven Machine Manufacturer?

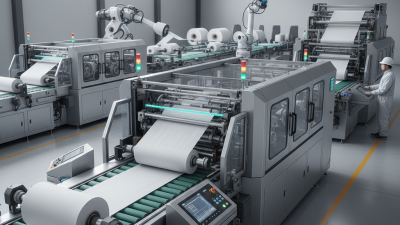

Choosing the right non woven machine manufacturer can significantly impact your production efficiency. In 2026, the market is saturated with options, making this decision crucial. You need a reliable partner to ensure quality machinery that meets your specific needs.

Considerations include the manufacturer’s reputation, years of experience, and customer feedback. A strong history in the industry often indicates trust. Yet, it’s essential to look beyond numbers. Visit facilities if possible. This gives you insight into their operations and product quality.

Additionally, reflect on your product specifications. What type of non woven fabric do you want to produce? Understanding your requirements helps narrow down your choices. Evaluate potential manufacturers meticulously, as a poor choice could lead to costly mistakes. The ideal non woven machine manufacturer should align with your goals and values.

Understanding Non Woven Machines and Their Applications

Non-woven machines play a critical role in various industries, including medical and hygiene products. The global non-woven fabric market is projected to reach $50 billion by 2026, according to a recent industry report. This growth highlights the increasing demand for non-woven materials, driven by applications like surgical gowns, face masks, and diapers.

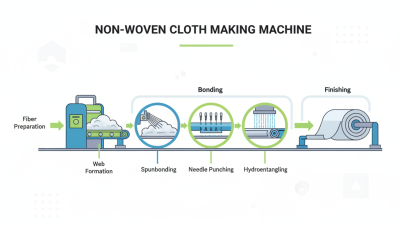

Understanding the applications of non-woven machines is vital. These machines produce fabrics without weaving, allowing for cost-effective and versatile manufacturing. For instance, in the healthcare sector, non-woven materials are essential. They offer lightweight, breathable, and disposable solutions. The durability of these products is often questioned, highlighting the need for continuous innovation and improvement in manufacturing techniques.

Despite advancements, challenges remain. Machine efficiency can vary widely among manufacturers. Issues like inconsistent fabric quality and production speed are common. These factors can impact product performance. It's essential for businesses to evaluate potential manufacturers carefully and seek those who prioritize quality and technology improvement. This ensures the final products meet industry standards and consumer expectations.

Key Factors to Consider When Choosing a Manufacturer

Choosing the right non-woven machine manufacturer can be challenging. There are key factors to consider that may impact your decision. Quality is essential when selecting a machine. A low-cost option might lead to higher maintenance costs over time. Think about the materials used and the technology implemented. Research thoroughly to ensure the manufacturer uses durable components.

Experience matters. A manufacturer with years in the industry may offer better support and understanding of market trends. Look for a company that has a track record of reliability. Customer reviews can provide insight into their reputation and service quality.

Tip: Ask for references and speak with past clients. This can give you a clearer picture of what to expect. Pay attention to their communication. A responsive manufacturer may save you time in future dealings. Evaluate their after-sales support as it is often overlooked. A solid warranty can also indicate confidence in their product.

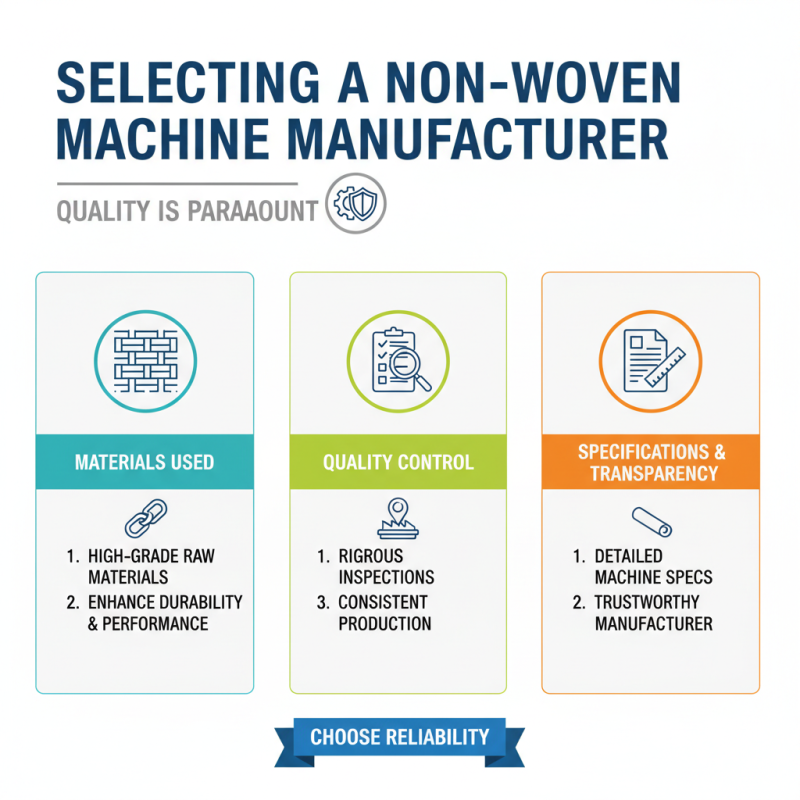

Evaluating the Quality and Technology of Non Woven Machines

When selecting a non woven machine manufacturer, quality is paramount. Pay attention to the materials used in production. High-grade raw materials enhance durability and performance. Look for manufacturers who emphasize rigorous quality control. They should provide detailed specifications for their machines.

Technology plays a critical role in non woven machinery. Advanced technology often leads to greater efficiency and lower waste. Investigate the types of technology employed in their machines. Innovative features could save time and resources. Ask about automation capabilities. Improved automation can streamline production processes.

Consider the manufacturer’s experience in the industry. A long-standing reputation may indicate stability and reliability. However, newer companies can offer fresh approaches. Engage in conversations with potential manufacturers. Their responses will reveal their expertise and willingness to innovate. Reflect on these factors carefully. Choosing a manufacturer is an investment in your production future.

Assessing After-Sales Support and Customer Service

When evaluating non woven machine manufacturers, after-sales support is often overlooked. Yet, studies indicate that 40% of production downtime results from inadequate support. Manufacturers should prioritize those with robust service programs. This includes quick response times and effective troubleshooting. A solid after-sales framework can significantly minimize operational disruptions.

Customer service is equally crucial. Research shows that 70% of customers consider service quality before repurchasing. Engaging with customers post-sale builds loyalty. It shows commitment beyond the initial transaction. Opt for manufacturers that maintain open communication channels. This can be through email, phone, or even live chat. Responsiveness reflects their dedication.

Some manufacturers may fall short. Limited service hours or lack of technical expertise can create frustration. Production lines are sensitive to delays. You might feel stuck with unresolved issues. Therefore, scrutinizing after-sales commitments is essential. The right choice will enhance your efficiency.

2026 How to Choose the Best Non Woven Machine Manufacturer? - Assessing After-Sales Support and Customer Service

| Dimension | Rating (1-5) | Comments |

|---|---|---|

| Response Time | 4 | Generally responds within 24 hours. |

| Technical Support | 5 | Expert assistance available at all times. |

| Availability of Spare Parts | 4 | Parts are mostly in stock, good logistics. |

| Training Provided | 5 | Comprehensive training sessions available. |

| Warranty Terms | 4 | Standard warranty with optional extensions. |

| Customer Feedback | 4 | Overall positive reviews from users. |

Comparing Manufacturer Pricing and Warranty Options

When selecting a non-woven machine manufacturer, pricing and warranty options are crucial. In 2023, a significant industry report revealed that 45% of buyers prioritize cost-effectiveness in machine purchases. With machines costing anywhere from $10,000 to over $100,000, understanding pricing structures is essential. Some manufacturers may offer a lower initial price but compromise on quality. This is where consumers must dig deeper.

Warranty terms vary widely. A recent survey indicated that 37% of manufacturers provide warranties that last less than a year. This can be risky. A longer warranty might suggest confidence in the machine’s reliability. However, not all extended warranties cover significant repairs. Maintenance costs can skyrocket if basic issues arise just outside warranty coverage.

Buyers should also be aware of hidden costs. Shipping fees, installation, and training can add significant expenses. Reports show that additional costs can increase the total price by 15% or more. Transparency with manufacturers is vital. Prospective buyers should ask direct questions about the warranty details and any potential extra fees. Making informed decisions can save considerable money in the long run.

Related Posts

-

How to Choose the Best Non Woven Fabric Manufacturing Machine for Your Needs

-

Best Non Woven Fabric Machines for Efficient Production and Quality Assurance

-

2025 Top Non Woven Fabric Making Machine Trends and Insights

-

What is a Non-Woven Cloth Making Machine and How Does It Work?

-

What is Nonwoven Industry: Insights into Its Growth and Applications

-

Best Non Woven Fabric Making Machines for Efficient Production?