Why is the Non Woven Fabric Industry Transforming Modern Manufacturing?

The non woven fabric industry is experiencing a significant transformation, reshaping modern manufacturing. Recent reports indicate that the global non woven fabric market is projected to reach $60 billion by 2028, growing at a CAGR of 5.5%. This growth stems from heightened demand across various sectors, including hygiene, medical, and automotive. The versatility of non woven materials allows for innovative applications, which drive their adoption in manufacturing processes.

However, the shift towards non woven fabrics is not without its challenges. Many manufacturers struggle to adapt to new technologies and materials. For instance, the production process can be resource-intensive. There is a noticeable gap in sustainable practices within some sectors of the non woven fabric industry. As companies strive for efficiency and lower costs, the pursuit of eco-friendly alternatives often falls short. Balancing profitability and environmental impact requires careful consideration and ongoing reflection.

Innovation continues to shape the landscape. New bonding technologies and fiber recycling methods promise to enhance the sustainability of non woven fabrics. As manufacturers navigate these changes, they must also address the complexities associated with quality control and consumer expectations. The importance of strategic adaptability in this evolving market cannot be overstated.

The Rise of Non Woven Fabrics in Manufacturing Sectors

The rise of non-woven fabrics is reshaping various manufacturing sectors. These fabrics, made from fibers that are bonded together, offer unique advantages. They are cost-effective, lightweight, and versatile. Many industries are adopting non-wovens for their durability and ease of production. From medical supplies to automotive interiors, the applications are vast and varied.

Tips: When considering non-woven fabrics, evaluate their lifecycle. How sustainable are they? Look for options that minimize environmental impact.

Another reason for their popularity is the speed of production. Non-woven fabrics can be produced quickly, meeting high demand efficiently. This flexibility appeals to manufacturers aiming for rapid turnaround. However, not all non-wovens are created equal. The quality can vary significantly among suppliers.

Tip: Always request samples before placing large orders. Assess the fabric's strength and usability thoroughly. In this fast-paced industry, it’s crucial to stay informed about emerging technologies that enhance fabric performance.

Growth of Non Woven Fabrics in Manufacturing Sectors

This chart illustrates the market share of non woven fabrics across various manufacturing sectors, highlighting the significant roles in automotive and medical applications, as well as other sectors like construction, home textiles, and hygiene products.

Key Advantages of Non Woven Fabrics Over Traditional Materials

The non-woven fabric industry is changing manufacturing practices significantly. Non-woven fabrics offer multiple advantages over traditional materials. According to a report from Smithers Pira, the global market for non-woven fabrics is expected to reach $41 billion by 2025. This growth is largely due to their versatility and cost-effectiveness.

Non-woven fabrics are lightweight and strong. They can be produced quickly, with less energy than woven materials. For example, a typical non-woven production line uses 70% less water than traditional textile processes. This efficiency can reduce the environmental impact considerably. Additionally, non-woven fabrics can be engineered for specific applications, providing unique properties such as water resistance or breathability.

Despite these benefits, there are challenges. Companies must navigate the complexities of sourcing raw materials. The reliance on petroleum-based sources poses sustainability questions. Also, maintaining consistent quality with rapid production processes can be daunting. Thus, while the potential of non-woven fabrics is immense, ongoing reflection is needed to address these critical issues.

Innovative Applications of Non Woven Fabrics in Various Industries

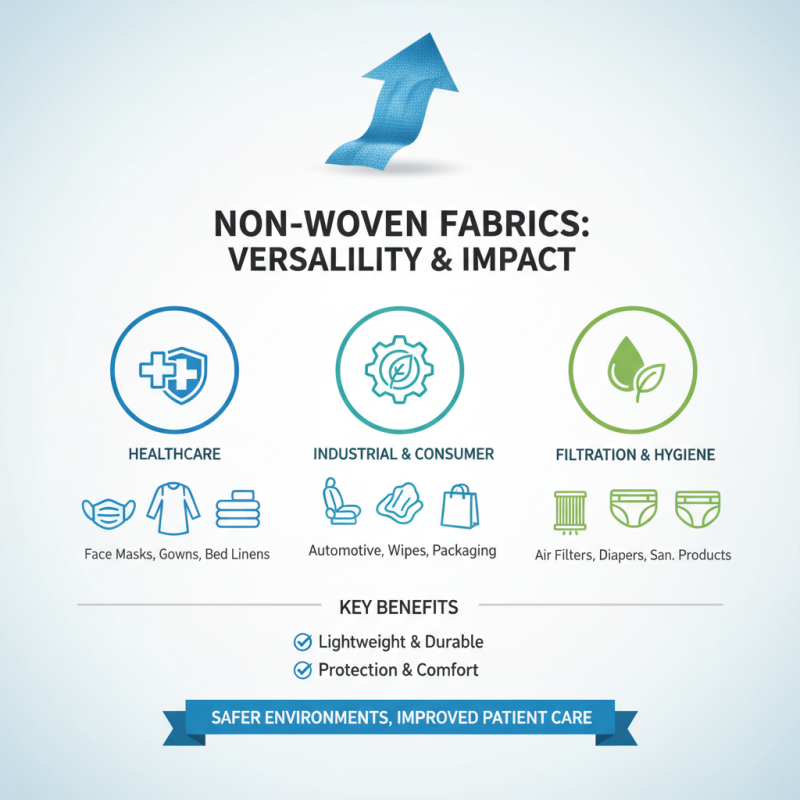

Non woven fabrics are gaining traction in multiple industries due to their versatility. In healthcare, they create essential items like face masks, gowns, and bed linens. These fabrics are lightweight yet durable, offering protection without sacrificing comfort. The adoption of non woven materials in medical applications contributes to safer environments and improved patient care.

In construction, non woven fabrics play a key role in insulation and roofing materials. They provide moisture resistance, helping to prolong the lifespan of buildings. Their lightweight nature makes them easy to transport, though careful consideration is needed in ensuring proper installation. This shift towards non woven solutions is not without challenges, including disposal and recycling issues that need addressing.

The automotive industry also benefits. Non woven fabrics are used in upholstery, soundproofing, and insulation. These textiles often reduce overall vehicle weight, improving fuel efficiency. However, manufacturers must balance performance with sustainability. As the industry evolves, finding eco-friendly sources for these fabrics remains a pressing concern.

Sustainability and Environmental Impact of Non Woven Fabrics

The rise of non woven fabrics is reshaping the manufacturing landscape. These materials are lightweight, versatile, and cost-effective. They find incredible applications, from medical to automotive sectors. However, the environmental implications are significant and require our attention.

Non woven fabrics are often made from synthetic fibers. This raises concerns regarding plastic waste. The production process can also be energy-intensive. Yet, many manufacturers are exploring eco-friendly alternatives. Biodegradable options and recyclable textiles are gaining traction. These innovations reflect a growing commitment to sustainability.

Challenges remain. Not all non woven products are designed with the environment in mind. The industry must address the carbon footprint and waste management more effectively. While strides are being made, there is still a long road ahead. Balancing efficiency and environmental responsibility is crucial for future success.

Future Trends and Challenges in the Non Woven Fabric Industry

The non woven fabric industry is evolving rapidly. Industry reports indicate a projected growth rate of 8.5% from 2022 to 2028. This growth is driven by increasing demand in sectors like hygiene, automotive, and construction. However, this rapid transformation poses several challenges.

Sustainability is at the forefront. Many manufacturers are shifting towards eco-friendly materials, yet recycled fiber usage remains low. Research highlighted that only 30% of non woven material comes from recycled sources. This reliance on virgin materials raises concerns. Additionally, production processes need modernization to reduce waste. The balance between innovation and resource utilization is delicate.

Market competition is intensifying. New entrants disrupt traditional players, yet many lack operational efficiency. In a landscape where innovation competes with cost, established companies must adapt or risk obsolescence. Industry experts note that investing in technology for efficiency is crucial. However, managing the transition period remains a significant challenge. The future of the non woven fabric industry hinges on embracing change while addressing these critical hurdles.

Why is the Non Woven Fabric Industry Transforming Modern Manufacturing? - Future Trends and Challenges in the Non Woven Fabric Industry

| Category | Current Market Size (USD Billion) | Projected Growth Rate (CAGR %) | Key Applications | Challenges |

|---|---|---|---|---|

| Hygiene Products | 15.3 | 6.5 | Diapers, Feminine Hygiene | Sustainability, Regulatory Compliance |

| Medical Applications | 10.1 | 7.8 | Surgical Masks, Gowns | Cost Management, Quality Control |

| Automotive | 5.6 | 5.0 | Interior Linings, Sound Insulation | Material Compatibility, Recycling Issues |

Related Posts

-

10 Best Facts About Non Woven Fabric You Should Know?

-

What is Non Woven Fabric and How is it Used in Everyday Products

-

Why Non Woven Fabric is Revolutionizing Industries and Everyday Products

-

What is Non Woven Textile Manufacturers and Their Key Benefits for Businesses

-

Top 2025 Uses and Benefits of Non Woven Fabric You Need to Know

-

How to Choose the Best Non Woven Fabric for Your Projects