Why Non Woven Fabric is Revolutionizing Industries and Everyday Products

The emergence of non woven fabric has significantly transformed various industries and everyday products, marking a pivotal shift in material technology. Unlike traditional woven materials, non woven fabric is engineered through a unique bonding process that allows for enhanced functionality, cost-effectiveness, and versatility. This innovation has led to its widespread adoption across sectors such as healthcare, agriculture, and consumer goods, where the demand for efficient, durable, and sustainable materials continues to grow.

In the healthcare industry, non woven fabric plays a crucial role in the production of medical supplies like masks, gowns, and other protective gear. Its lightweight and breathable properties offer comfort while ensuring safety for both medical professionals and patients. Moreover, the fabric's ability to be produced in bulk with minimal waste aligns perfectly with the increasing emphasis on sustainability and environmental responsibility in contemporary manufacturing processes.

The impact of non woven fabric extends into everyday life as well, where it is utilized in products ranging from household items to fashion accessories. This versatility demonstrates how non woven fabric is not only revolutionizing industrial applications but also enhancing the quality and functionality of the products that consumers encounter daily. As we delve deeper into this topic, it becomes clear that non woven fabric is at the forefront of modern innovation, shaping the future of materials in countless ways.

The Definition and Composition of Non Woven Fabrics

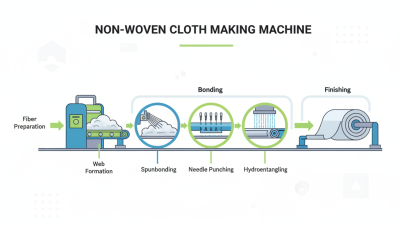

Non woven fabrics are engineered textiles created by bonding fibers together through various methods such as heat, chemical, or mechanical means. Unlike traditional woven fabrics, which consist of yarn interlacing, non woven fabrics derive their structure from the random arrangement of fibers, making them unique in their composition. This innovative approach allows for a variety of properties and functionalities, catering to a wide range of applications across different industries.

The composition of non woven fabrics typically includes synthetic fibers like polypropylene, polyester, or polyamide, although natural fibers such as cotton or rayon can also be utilized. The choice of fibers greatly influences the characteristics of the final product, such as strength, durability, breathability, and absorbency. Additionally, the manufacturing processes can vary, with options like spunbond, meltblown, and needle-punch techniques that contribute to the diverse nature and performance of non woven fabrics. This versatility not only revolutionizes the textile industry but also enhances everyday products, from personal hygiene items to industrial materials.

Historical Development and Evolution of Non Woven Fabrics

The historical development of non-woven fabrics dates back to the early 20th century when they were initially created through simple bonding techniques involving fibers.

The industrial revolution further propelled advancements in the manufacturing processes, leading to the introduction of synthetic fibers in the 1960s. This shift marked a significant evolution as non-woven fabrics could now be produced on a larger scale with enhanced durability and versatility, paving the way for their application in various sectors.

Today, non-woven fabrics have established themselves as powerful materials in both industrial and consumer products. Their ability to be engineered for specific functions makes them suitable for use in medical supplies, filtration systems, and even household items. The versatility of non-woven fabrics has led to innovations in design and functionality, making them an integral part of many daily uses.

Tips: When selecting non-woven products, look for those made from recycled or eco-friendly materials to contribute to sustainability. Additionally, consider the application of the fabric; for example, choose medical-grade non-wovens for health-related uses to ensure safety and effectiveness.

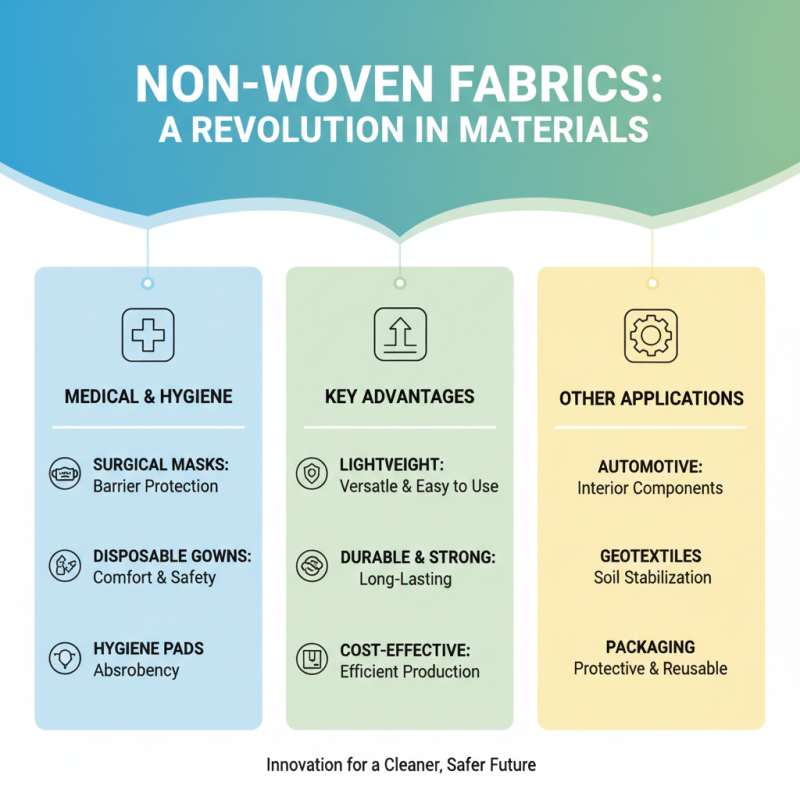

Key Advantages of Non Woven Fabrics in Various Industries

Non woven fabrics have emerged as a game-changer across various industries, thanks to their unique properties and versatility. One of the primary advantages of non woven fabrics is their lightweight nature, making them ideal for applications where traditional woven materials may be too heavy or cumbersome. In medical and hygiene products, for instance, non woven fabrics are utilized in disposable items such as surgical masks, gowns, and hygiene pads, providing not only comfort but also effective barrier protection against contaminants.

Moreover, non woven fabrics offer excellent durability and strength, which enhances their usability in sectors such as automotive and construction. These fabrics can be engineered to withstand harsh conditions, making them suitable for insulation, acoustic dampening, and filtration systems. Their ability to be produced in various thicknesses and densities allows for tailored solutions that meet specific industrial needs, driving innovation and efficiency. Alongside these practical benefits, non woven fabrics are increasingly recognized for their eco-friendliness, as many variants are made from recyclable or biodegradable materials, aligning with the growing demand for sustainable products in today's market.

Applications of Non Woven Fabrics in Everyday Products

Non woven fabrics are transforming various aspects of daily life through their diverse applications. In the realm of personal care, for instance, these materials are commonly found in products like facial masks, wipes, and hygiene pads. Their lightweight, breathable, and absorbent qualities make them ideal for these uses, ensuring comfort and efficiency for consumers. Additionally, non woven fabrics are essential in medical technologies, contributing to surgical gowns, sterile dressings, and other critical items that prioritize cleanliness and safety.

Tips: When selecting non woven products, look for options that emphasize eco-friendliness. Many manufacturers are now producing biodegradable versions of these fabrics, aligning with sustainability goals without compromising performance.

Beyond personal care, non woven fabrics have made significant inroads into the home and household goods sector. They are often utilized in products like shopping bags, cleaning cloths, and gardening materials. Their ability to be produced in various textures and weights allows for customizable solutions suited for different needs, from durable reusable bags to lightweight disposable cleaning rags.

Tips: For home projects, consider using non woven fabrics for DIY crafts or organization solutions. Their versatility can spark creativity while also being practical and resourceful.

Applications of Non Woven Fabrics in Everyday Products

Future Trends and Innovations in Non Woven Fabric Technology

The evolution of non-woven fabric technology is poised to transform various industries and everyday products significantly. In recent years, the global non-woven fabrics market has experienced substantial growth, with forecasts indicating a compound annual growth rate (CAGR) of approximately 8.7% from 2021 to 2028. This surge can be attributed to innovative developments in manufacturing processes, including the advent of advanced bonding methods such as thermal, chemical, and mechanical treatments, which enhance the durability and functionality of these fabrics.

Looking ahead, several trends are emerging in the non-woven fabric sector, particularly in sustainability and eco-friendliness. The increased focus on recycled materials and biodegradable options is driving innovations that cater to environmentally conscious consumers. According to a recent industry report, over 30% of new non-woven products are now designed with sustainability in mind, leading to a rise in the use of materials like organic fibers and recycled plastics. Additionally, advancements in technology are fostering applications in diverse fields such as healthcare, where non-woven fabrics are being developed for use in hygiene products, surgical gowns, and masks, significantly improving safety standards and reducing waste. These innovations underscore the ongoing shift toward more sustainable practices in fabric production, setting a new benchmark for future developments.

Why Non Woven Fabric is Revolutionizing Industries and Everyday Products - Future Trends and Innovations

| Application Area | Key Innovations | Sustainability Impact | Market Growth Rate |

|---|---|---|---|

| Medical Products | Antimicrobial properties, biodegradable materials | Reduction of waste through single-use alternatives | 8% CAGR |

| Hygiene Products | Advanced filtration technology | Use of recycled fibers | 10% CAGR |

| Automotive | Lightweight composites for interiors | Sourcing of sustainable materials | 6% CAGR |

| Geotextiles | Improved soil stabilization | Natural fiber reinforcements | 7% CAGR |

| Construction | Waterproof and breathable membranes | Recyclable materials | 5% CAGR |

Related Posts

-

What is Non Woven Fabric and How is it Used in Everyday Products

-

How to Choose the Best Non Woven Fabric for Your Projects

-

Why Non Woven Fabric Manufacturers Are Key to Sustainable Industry Solutions

-

Top 2025 Uses and Benefits of Non Woven Fabric You Need to Know

-

What is Non Woven Textile Manufacturers and Their Key Benefits for Businesses

-

What is a Non-Woven Cloth Making Machine and How Does It Work?