What is Non Woven Textile Manufacturers and Their Key Benefits for Businesses

In recent years, the demand for non-woven textiles has surged, driven by their versatile applications across various industries, including healthcare, hygiene, agriculture, and automotive. According to a report by Market Research Future, the global non-woven fabrics market is projected to reach approximately USD 59.97 billion by 2027, growing at a compound annual growth rate (CAGR) of 6.8% from 2020 to 2027. This growth is largely attributed to the increasing utilization of non-woven materials in personal protective equipment (PPE) and medical applications, particularly highlighted during global health crises.

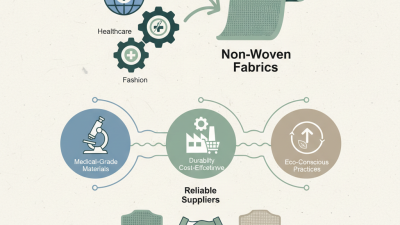

Non woven textile manufacturers play a crucial role in this expanding market by providing innovative solutions that meet the evolving needs of businesses. They leverage advanced production techniques and sustainable materials to create products that are not only cost-effective but also environmentally friendly. The ability to customize non-woven fabrics for specific purposes—whether for durability, filtration, or absorbency—offers companies a competitive edge in their respective fields. As industries worldwide continue to prioritize efficiency and sustainability, the contributions of non woven textile manufacturers will remain pivotal in shaping future market trends and business strategies.

Understanding Non Woven Textiles: Definition and Characteristics

Non-woven textiles are a unique category of fabric that differ significantly from traditional woven and knitted materials. Defined as fabric structures that are bonded together without the need for weaving, these textiles are produced by entangling fibers through various methods such as heat, chemical, or mechanical means. This process allows for a wide variety of materials to be used, including synthetic fibers, natural fibers, or a combination of both, leading to versatile applications across numerous industries.

One of the key characteristics of non-woven textiles is their lightweight and breathable nature, making them ideal for products ranging from medical supplies to industrial filters. Additionally, these textiles can be engineered for specific functionalities, such as water resistance, absorbency, and durability. Their production involves less energy and water compared to traditional textiles, offering an environmentally friendly alternative for businesses looking towards sustainable practices. The flexibility in design and functionality allows manufacturers to cater to specialized needs, enhancing product offerings and providing significant benefits in terms of cost-efficiency and innovation.

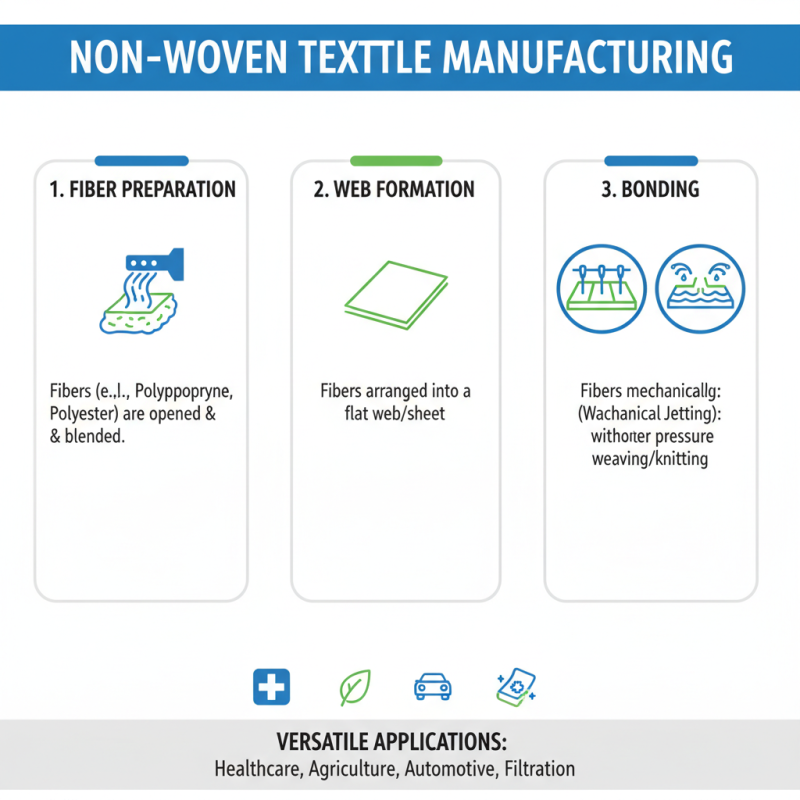

The Manufacturing Process of Non Woven Textiles and Technologies Used

The manufacturing process of non-woven textiles involves several innovative techniques that differentiate them from traditional woven or knitted fabrics. One of the primary methods employed is the mechanical bonding process, where fibers are entangled through needle punching and water jetting, creating fabric without the need for weaving. This allows for greater flexibility in design and structure, making non-woven textiles versatile for various applications from healthcare to agriculture.

In addition to mechanical bonding, chemical bonding plays a critical role in non-woven fabric production. Here, bonding agents are used to bind fibers together, enhancing the strength and durability of the textile. Another notable technology is thermal bonding, which involves using heat to fuse the fibers. This method allows for a rapid production process and the creation of lightweight, soft textiles. The combination of these technologies enables manufacturers to produce customized non-woven materials that cater to specific industry needs, driving efficiency and fostering innovation within various sectors.

Key Benefits of Using Non Woven Textiles for Businesses

Non-woven textiles have become essential for businesses across various industries due to their unique properties and benefits. One of the primary advantages of using non-woven fabrics is their cost-effectiveness. According to a report by Smithers Pira, the global non-woven fabric market is projected to surpass USD 50 billion by 2027, driven by their versatility and lower manufacturing costs compared to woven textiles. This financial efficiency allows companies to reduce production expenses while maintaining high-quality output.

Another key benefit of non-woven textiles is their durability and strength. These materials are engineered to withstand various conditions, making them ideal for applications ranging from medical supplies to automotive components. A study by the Nonwovens Institute highlighted that non-woven fabrics exhibit superior resistance to water, chemicals, and abrasion, which enhances their lifespan and reliability in demanding environments. Businesses that utilize these textiles can experience lower maintenance costs and reduced product replacement rates.

Tips: When considering non-woven textiles, ensure that you evaluate the specific needs of your project. Understanding the varying materials and their properties, such as biodegradability and moisture resistance, can significantly impact the efficiency of your operations. Additionally, collaborating with manufacturers who prioritize sustainability can not only enhance your brand's image but also align with emerging consumer preferences for eco-friendly products.

What is Non Woven Textile Manufacturers and Their Key Benefits for Businesses - Key Benefits of Using Non Woven Textiles for Businesses

| Benefit | Description | Industry Applications |

|---|---|---|

| Cost-Effective | Non woven textiles are generally cheaper to produce compared to traditional woven fabrics, leading to lower costs for businesses. | Healthcare, Packaging |

| Versatility | Can be manufactured in various weights and textures, making them suitable for multiple applications. | Fashion, Automotive |

| Eco-Friendly Options | Many non woven fabrics are made from recycled materials and are biodegradable, appealing to environmentally conscious consumers. | Consumer Goods, Home Textiles |

| Lightweight | Non woven textiles are often lighter than woven options, which can reduce shipping and handling costs. | Construction, Agriculture |

| Durability | They tend to be strong and resistant to wear, making them ideal for long-lasting products. | Healthcare, Industrial |

Applications of Non Woven Textiles Across Various Industries

Non-woven textiles are gaining traction across a variety of industries due to their unique properties and versatility. One of the most prominent applications is in the healthcare sector, where non-woven materials are utilized for surgical gowns, face masks, and disposable bedding. These textiles provide excellent barrier protection, reducing the risk of contamination and enhancing patient safety. Their lightweight nature and breathability make them ideal for use in medical environments, ensuring comfort for both healthcare workers and patients.

Another significant application is in the automotive industry, where non-woven textiles are used for soundproofing, insulation, and interior linings. These materials contribute to vehicle lightweighting, which is essential for improving fuel efficiency and overall performance. Additionally, non-woven textiles are employed in filtration systems, offering effective solutions to air and liquid purification needs across various sectors, including manufacturing and environmental services. This adaptability not only enhances product performance but also supports businesses in meeting sustainability goals by reducing material waste and embracing eco-friendly substitutes.

Applications of Non Woven Textiles Across Various Industries

Future Trends in Non Woven Textile Manufacturing and Sustainability

The future of non-woven textile manufacturing is progressively moving towards greater sustainability, driven by the need to reduce environmental impact while meeting market demands. As consumers become more environmentally conscious, manufacturers are exploring innovative, eco-friendly materials such as biodegradable fibers and recycled content. This shift not only helps in minimizing waste but also aligns with global sustainability goals, positioning non-woven textiles favorably in competitive markets.

The integration of advanced technologies, such as automation and artificial intelligence, is another critical trend shaping the future of non-woven textiles. These innovations enhance production efficiency and allow for customization on a larger scale, catering to diverse customer needs. Moreover, the focus on sustainability encourages the development of closed-loop systems, where end-of-life products can be recycled or repurposed, further reducing the carbon footprint associated with textile production. This investment in sustainable practices not only appeals to eco-conscious consumers but also aligns with corporate social responsibility initiatives, making non-woven textiles a driving force in the move towards a more sustainable future in the textile industry.

Related Posts

-

Why Non Woven Fabric Manufacturers Are Key to Sustainable Industry Solutions

-

What is Non Woven Fabric and How is it Used in Everyday Products

-

Top Non Woven Fabric Suppliers You Need to Know for Your Business

-

2025 Top Non Woven Fabric Making Machine Trends and Insights

-

How to Choose the Best Non Woven Fabric Manufacturing Machine for Your Needs

-

What is Nonwoven Industry: Insights into Its Growth and Applications