What is the Nonwoven Industry and its Impact on Modern Manufacturing

The nonwoven industry has emerged as a pivotal segment of modern manufacturing, revolutionizing the way materials are produced and utilized across various sectors. According to a recent report by Smithers Pira, the global nonwoven fabric market is projected to reach an estimated value of USD 50 billion by 2028, demonstrating an annual growth rate of approximately 6.7%. This rapid expansion reflects the increasing demand for lightweight, durable, and cost-effective materials that nonwoven products offer, facilitating advancements in industries such as healthcare, automotive, and construction.

As highlighted by Dr. Julia Marsh, a leading expert in textile engineering, "The nonwoven industry is not just about fabric; it's about creating innovative solutions that enhance product performance and sustainability." This sentiment encapsulates the industry's impact on modern manufacturing, where nonwoven materials are being leveraged for their versatility and efficiency. From disposable medical gowns to automotive soundproofing, the applications of nonwoven products are vast, making them essential in meeting both consumer needs and environmental considerations.

In summary, the nonwoven industry stands at the forefront of manufacturing innovation, characterized by its robust growth and transformative applications. The insights from industry experts, coupled with substantial market data, underscore the critical role that nonwovens play in shaping the future of manufacturing and addressing the challenges of a rapidly evolving market landscape.

Definition and Overview of the Nonwoven Industry

The nonwoven industry is an essential segment of modern manufacturing, characterized by the production of fabrics that are not woven or knitted but instead bonded together through various processes. Nonwoven fabrics are typically made from synthetic or natural fibers and offer flexibility, durability, and cost-effectiveness, leading to their widespread application in various sectors, including medical, automotive, and construction. According to a report by Smithers, the global nonwoven fabric market was valued at approximately $48 billion in 2020 and is projected to reach around $66 billion by 2025, reflecting a compound annual growth rate (CAGR) of over 6%.

One of the critical aspects of the nonwoven industry is its ability to adapt rapidly to changing market demands. With an increasing focus on sustainability, manufacturers are innovating by using biodegradable and recyclable materials in their production processes. As per Freedonia Group, the demand for sustainable nonwoven products is expected to increase significantly, driven by consumer preference for eco-friendly solutions. The versatility of nonwoven materials allows them to be tailored for specific applications, such as hygiene products, filtration, and geotextiles, making them indispensable in addressing modern manufacturing challenges while promoting a more sustainable future.

Historical Development of Nonwoven Fabrics and Technologies

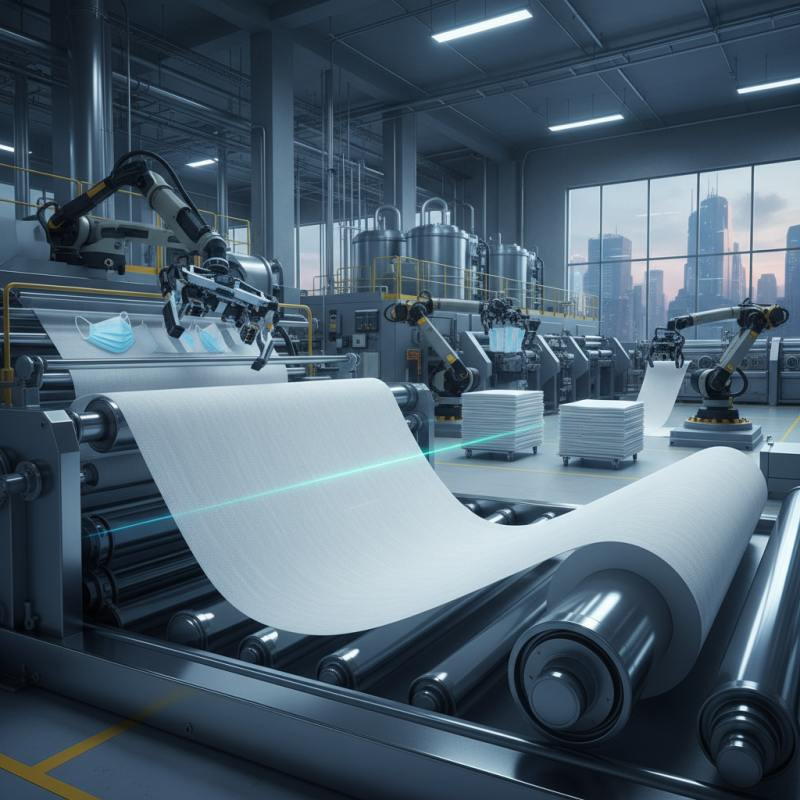

The nonwoven industry has a rich historical backdrop that underscores its evolution and integration into modern manufacturing. Initially, nonwoven fabrics were developed in the mid-20th century, primarily for the medical industry, with the invention of spunbond and meltblown technologies. These processes allowed for the efficient production of lightweight, absorbent materials that met specific needs, paving the way for a diverse range of applications.

Over the decades, the technological advancements in nonwoven fabric production have expanded into various sectors, including automotive, construction, and personal care. The ability to tailor properties such as filtration, strength, and softness has made nonwovens indispensable in everyday products. For instance, they are now commonly used in hygiene products, geotextiles, and protective clothing. The versatility of nonwoven materials has helped industries reduce waste and enhance efficiency, aligning with modern manufacturing's focus on sustainability.

Tips: When exploring the nonwoven materials market, consider their lifecycle and environmental impact. Opting for biodegradable options can improve your sustainability efforts. Additionally, staying updated on innovations in nonwoven technologies can provide insights into emerging applications that may benefit your manufacturing processes.

What is the Nonwoven Industry and its Impact on Modern Manufacturing

| Year | Milestone | Technological Development | Major Applications |

|---|---|---|---|

| 1965 | Commercialization of Nonwoven Fabrics | Introduction of thermal bonding technology | Hygiene products, medical textiles |

| 1970s | Rapid Growth in Market Demand | Advancements in spunbond technology | Personal care, automotive, and filtration |

| 1980s | Diversification of Nonwoven Products | Development of needlepunching | Geotextiles, insulation materials |

| 2000s | Technological Innovations for Sustainability | Biodegradable nonwovens and eco-friendly processes | Medical gowns, sanitary items |

| 2020s | Increase in Use for Personal Protective Equipment (PPE) | Enhanced filtration technologies | Face masks, specialized disposable coverings |

Key Manufacturing Processes in the Nonwoven Industry

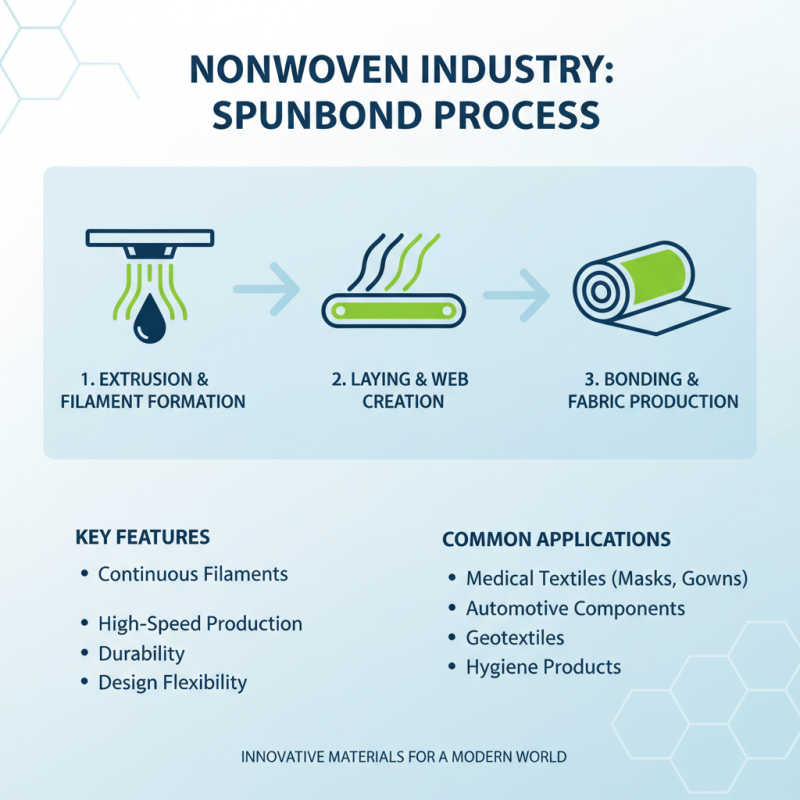

The nonwoven industry plays a crucial role in modern manufacturing by utilizing innovative processes to produce a wide range of materials. One of the key manufacturing methods is the spunbond process, where continuous filaments are extruded and laid down to form a fabric. This process allows for high-speed production and is commonly used in applications ranging from medical textiles to automotive components, providing durability and flexibility in design.

Another significant process is the needlepunching method, which involves entangling fibers mechanically to create nonwoven fabrics. This technique is particularly popular for producing insulation materials and geotextiles. The versatility of needlepunching allows manufacturers to tailor the properties of the fabric, such as thickness, density, and strength, catering to specific demands in various industries, including construction and filtration. Overall, these manufacturing processes highlight the nonwoven industry's capacity to meet the evolving needs of diverse sectors while maintaining efficiency and sustainability.

Applications of Nonwoven Materials in Various Sectors

Nonwoven materials have become integral to various sectors, significantly impacting modern manufacturing. One of the most prominent applications is in the medical industry, where nonwoven fabrics are utilized for surgical masks, gowns, and drapes. These materials offer essential benefits such as breathability, fluid resistance, and disposable convenience, making them ideal for maintaining hygiene in healthcare settings. Additionally, nonwoven textiles are crucial in producing disposable products like diapers and feminine hygiene items, contributing to enhanced user comfort and safety.

In the automotive sector, nonwoven fabrics are employed for sound insulation, upholstery, and filtration systems. Their lightweight nature and versatility help in reducing the overall weight of vehicles, which translates to improved fuel efficiency and lower emissions. Furthermore, nonwoven materials find applications in construction, serving as protective barriers and insulation materials. These fabrics not only provide durability and weather resistance but also contribute to energy efficiency in buildings. As industries continue to recognize the advantages of nonwoven materials, their presence and applications in manufacturing will likely continue to grow, driving innovation and sustainability across various sectors.

Environmental Impact and Sustainability Practices in Nonwoven Production

The nonwoven industry plays a pivotal role in modern manufacturing, particularly in sectors like hygiene, medical supplies, and packaging. However, the environmental impact of nonwoven production is a growing concern. Traditional nonwoven materials, often derived from petroleum-based sources, contribute to pollution and waste, making sustainability practices crucial. Manufacturers are increasingly exploring eco-friendly alternatives, such as biodegradable fibers and recyclable materials, to minimize their carbon footprint.

One effective strategy for enhancing sustainability in nonwoven production is adopting a life cycle assessment (LCA) approach. This method evaluates the environmental impacts of a product from raw material extraction through manufacturing to disposal. By identifying crucial areas for improvement, companies can implement targeted changes that reduce resource consumption and environmental degradation.

Tips for sustainable practices in the nonwoven industry include investing in renewable energy sources for production facilities, optimizing water usage during manufacturing processes, and collaborating with suppliers who prioritize eco-friendly practices. Additionally, educating consumers about the benefits of choosing sustainable nonwoven products can drive demand and encourage responsible consumption. Implementing these strategies not only benefits the planet but can also enhance a brand's reputation in an increasingly eco-conscious market.

Related Posts

-

2025 Top Non Woven Fabric Making Machine Trends and Insights

-

Top Non Woven Material Applications in 2025 and Future Trends

-

Why Non Woven Fabric Manufacturers Are Key to Sustainable Industry Solutions

-

How to Choose the Best Non Woven Fabric Manufacturing Machine for Your Needs

-

Top 10 Innovative Machines Transforming the Textile Industry in 2023

-

2025 How to Choose the Best Non Woven Cutting Machine for Your Needs