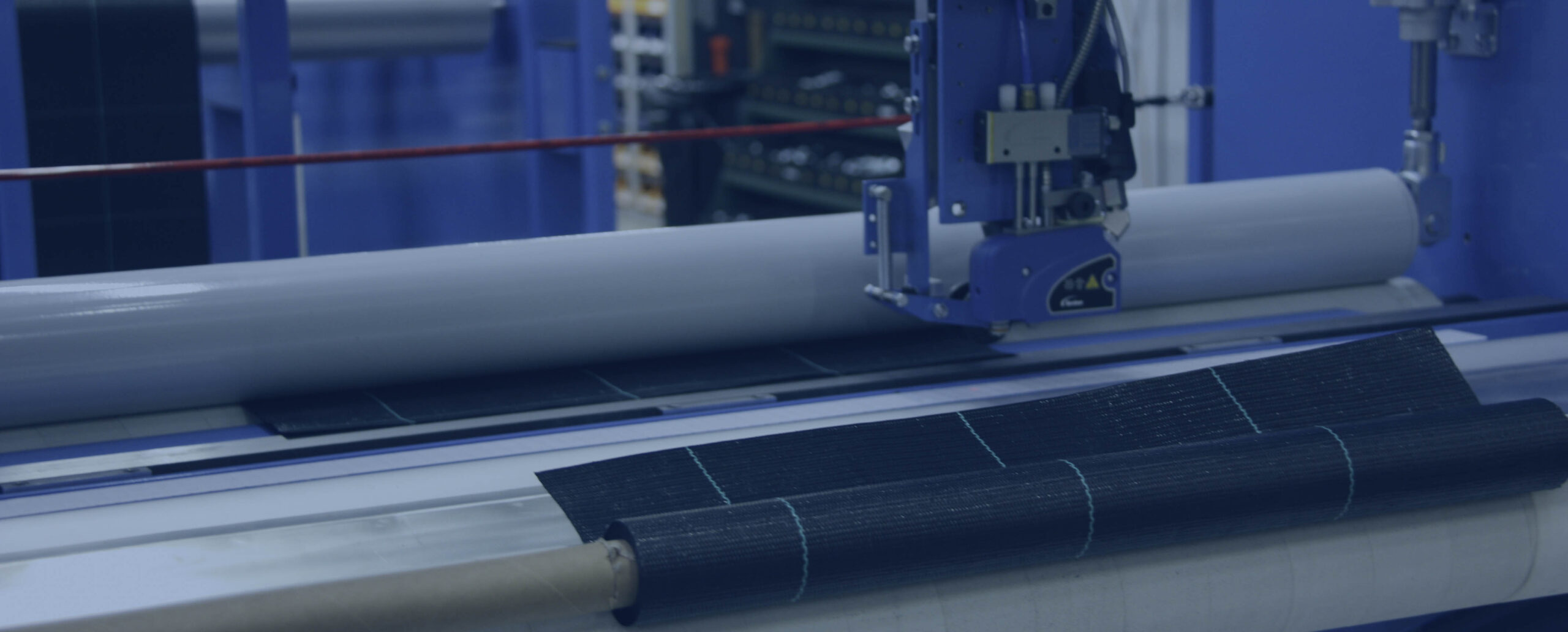

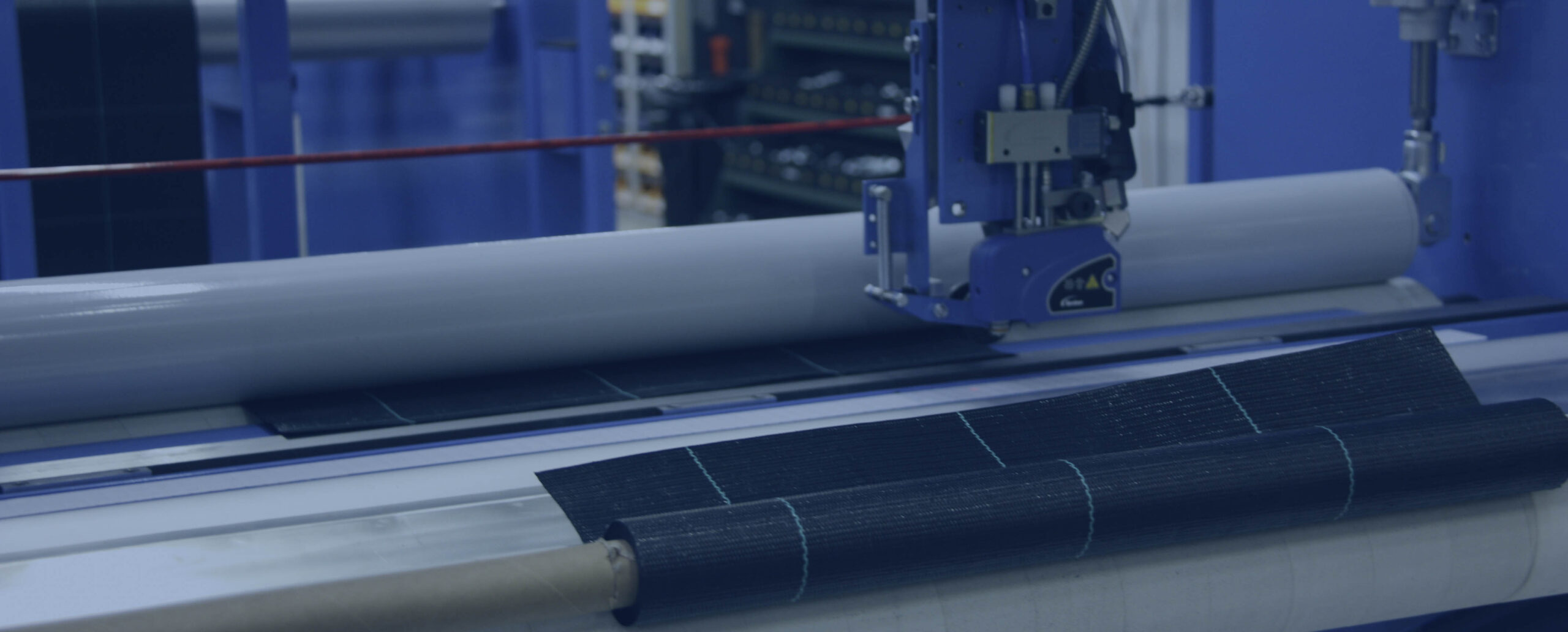

For over forty years, CAMPEN Machinery A/S has supplied automated winding machine solutions to manufacturers of nonwovens, geotextiles, technical textiles, and specialty films. Our focus is on robust engineering, consistently high quality, and low total operating costs. Each automated winding machine is designed to match your production line, supporting high uptime and precise roll handling. Our technical teams cooperate closely with you from initial concept through commissioning, ensuring each installation meets your process needs and product specifications.

A reliable automated winding machine forms the backbone of roll goods production. With decades of knowledge, CAMPEN delivers proven, easy-to-operate systems for centre-driven, surface-driven, or combined winding. Our servo-controlled technology maintains stable web tension, ideal for handling diverse materials and variable production speeds.

Our automated winding machine can process geotextiles, airlaid, spunlace, synthetic felts, artificial leather, fibreglass mats, and more. Each solution is adapted for your production targets—whether continuous in-line winding or flexible, stand-alone rewinding is required.

Consistent roll quality is achieved through advanced electronics and mechanical design. Servo drives and modern software keep process variables stable, even during high-speed acceleration and deceleration. Recipe-based HMI interfaces ensure quick and repeatable job changeovers, while advanced measurement and tension monitoring avoid defects and support traceability.

Safe operation is built into every CAMPEN winding machine. Straightforward maintenance intervals and long-term spare part support ensure reliable production for years. Clear visual interfaces and robust construction translate to easy cleaning and daily handling.

Your production line is unique. We tailor each automated winding machine for your specific floorplan, upstream and downstream equipment, and material flow. Whether you need high-speed in-line winding or off-line slitting, the same reliable control platform is used throughout. Machines are prepared for modern connectivity and scalable automation.

Our winding systems can include integrated stretch film wrapping, automatic core insertion, and labelling for a streamlined finish. The CAMPEN team stands ready to support your project from feasibility studies to lifecycle service and upgrades.

If you are specifying a new nonwoven line or upgrading older geotextile winding equipment, supply your targets for product type, roll width, diameter, weight, and speed. Our team will recommend a machine layout, automation level, and practical solutions for efficient operation and top product quality. We offer full documentation and clear project management, so you can operate your new equipment with confidence, safety, and low downtime.

Need help with your automated winding machine project? Talk to our engineers or request an assessment today. Learn more at www.artandthemachine.com/nonwoven or contact us at www.artandthemachine.com/contact-us.

Peder Helbo

Sales Director